Reciprocating Pumps are Vital for Industry Success

Updated: 03 Nov 2024

167

Reciprocating pumps are powerful machines used across various industries, from water treatment to oil and gas, due to their ability to generate high pressure with precision. Unlike other pumps, reciprocating pumps use a back-and-forth motion, driven by pistons or plungers, to move fluids effectively. This unique mechanism makes them ideal for applications that require controlled flow rates, especially in situations where consistency and reliability are essential.

These pumps offer several advantages, including the ability to handle viscous fluids and create uniform pressure in demanding environments. While they do require maintenance due to their moving parts, the precision and efficiency they provide make them a valuable asset in industrial processes. In this article, we’ll explore how reciprocating pumps work, their various types, and the key benefits they bring to the table. Whether you’re new to this technology or looking to deepen your understanding, this guide will help you see why reciprocating pumps are so essential in today’s industrial landscape.

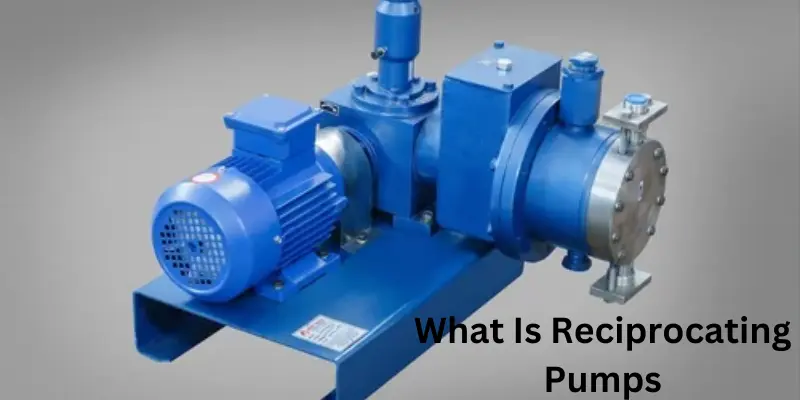

What Is Reciprocating Pumps?

A reciprocating pump is a machine that moves liquids by using a simple back-and-forth motion, like how you might move a bicycle pump to fill a tire with air. Imagine a cylinder with a piston inside it, much like a big syringe. When the piston pulls back, it creates space, and the liquid is drawn into the pump. Then, when the piston pushes forward, it forces the liquid out, creating pressure.

These pumps are commonly used to move liquids, especially when high pressure is needed, like pushing water up to tall buildings or moving oil through pipelines. Reciprocating pumps work in a steady, controlled way, making them great for jobs where precise amounts of liquid need to be moved. Even though they’re a bit more complex and need regular care, their accuracy and power make them really useful in many industries.

You May Also Visit It!

Spray Arc Welding – Step by Step Guide – Need Metals

Pre Coat Metal | Define Complete Guide- Need Metals

Mcelroy Metals – Types, Uses And Properties – Need Metals

Will Magnets Stick to Stainless Steel Refrigerator – Complete Guide

Key Components of a Reciprocating Pump

A reciprocating pump is made up of several important parts that work together to move liquids. Here’s a simple explanation of each key part:

- Cylinder: The cylinder is like the “body” of the pump where the action happens. It holds the liquid that will be moved in and out.

- Piston or Plunger: This part moves back and forth inside the cylinder, just like a plunger in a syringe. When it pulls back, it brings liquid into the pump, and when it pushes forward, it pushes the liquid out.

- Valves (Suction and Delivery Valves): Think of these as little doors that control the flow of liquid. The suction valve opens to let liquid into the pump, and the delivery valve opens to let liquid out. They only open in one direction, making sure the liquid flows the right way.

- Crankshaft: The crankshaft is what powers the pump, often connected to an engine or motor. It helps move the piston or plunger back and forth, creating the pumping action.

- Air Vessel: This part helps smooth out the flow of the liquid, so it doesn’t come out in “spurts.” It keeps the pressure steady, making the pump work more efficiently.

Each of these parts plays an essential role in helping the pump move liquids with precision and power. By working together, they make reciprocating pumps a reliable choice for tasks that need consistent and controlled liquid flow.

Types of Reciprocating Pumps

Reciprocating pumps come in different types, and each type has its own special way of working. Here are the main types explained simply:

- Single-Acting Pumps: In these pumps, the piston moves back and forth but only pushes liquid out on one side. When the piston moves forward, it pushes liquid out through the delivery valve. When it pulls back, it creates a space for liquid to come in through the suction valve. This means that liquid only flows out during one part of the cycle.

- Double-Acting Pumps: These pumps are a bit more powerful because the piston can push liquid out on both sides! When the piston moves one way, it pushes liquid out from one side, and when it moves the other way, it pushes liquid out from the other side. This allows for a continuous flow of liquid, making it more efficient for certain jobs.

- Hand-Operated Pumps: These are the simplest type of reciprocating pumps, where a person uses a handle to move the piston. They are often used for small tasks, like pumping water from a well or filling up a container.

- Power-Operated Pumps: These pumps use an engine or motor to move the piston. Because they are powered by machines, they can handle larger jobs and move more liquid quickly. They are commonly used in industries where a lot of liquid needs to be pumped.

Each type of reciprocating pump has its own advantages and is used in different situations. Understanding these types helps people choose the right pump for their needs!

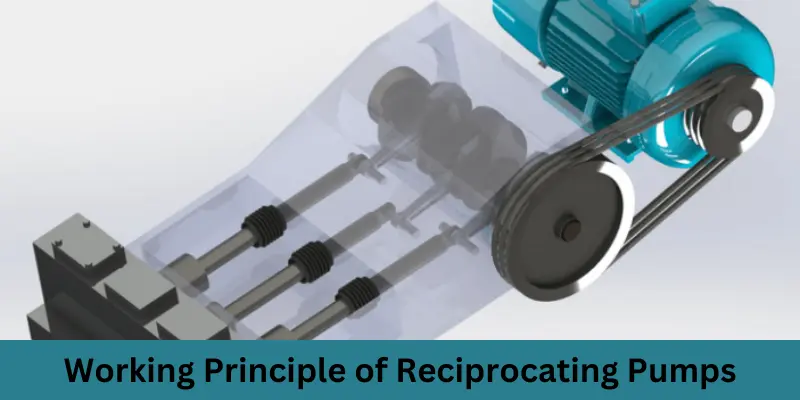

Working Principle of Reciprocating Pumps

The working principle of reciprocating pumps is quite interesting and easy to understand! Here’s how they work in simple steps:

- Creating Space: When the piston inside the pump pulls back (like when you pull a plunger out of a syringe), it creates a space in the cylinder. This space makes a low pressure, which allows the liquid to be sucked into the pump through the suction valve, which is like a door that only opens one way.

- Filling Up: As the piston continues to move back, the cylinder fills up with liquid. This is like filling up a balloon with air—the more you pull back, the more air (or in this case, liquid) comes in.

- Pushing the Liquid Out: Next, the piston moves forward. When it pushes forward, it creates pressure that forces the liquid out through the delivery valve, which opens to let the liquid flow out. It’s like when you push down on a syringe; the liquid inside is pushed out through the tip.

- Repeating the Cycle: This process happens over and over again—pulling back to fill, then pushing forward to empty. In a single-acting pump, this happens on one side of the piston. In a double-acting pump, while one side is pushing liquid out, the other side is pulling in more liquid, allowing for a continuous flow.

By working this way, reciprocating pumps can move liquids with a lot of pressure and control, making them very useful in many places, like factories and water systems!

Applications of Reciprocating Pumps

Reciprocating pumps are used in many different places because they are great at moving liquids. Here are some of the key applications where you can find these pumps in action:

- Water Supply Systems: Reciprocating pumps are often used to move water from one place to another, such as from a well to a home or building. They help ensure that everyone has access to clean water when they need it.

- Oil and Gas Industry: In the oil and gas industry, these pumps are essential for moving oil from the ground through pipelines. They can handle thick liquids, making them perfect for this job.

- Chemical Processing: Reciprocating pumps are used to transfer various chemicals safely in factories. They help in mixing and moving different chemical solutions, ensuring that everything runs smoothly in the production process.

- Mining Operations: In mining, these pumps are used to remove water from mines or to transport slurry, which is a mix of water and solid materials. This helps keep the mining area dry and allows for easier extraction of minerals.

- Food and Beverage Industry: These pumps are also used to move liquids like juices, oils, and sauces. They are great for handling food products because they can ensure the right amount of liquid is moved without contamination.

- Pharmaceuticals: In the pharmaceutical industry, reciprocating pumps help move medicines and other liquids in a controlled way. This is crucial for ensuring that medications are produced safely and effectively.

In all these applications, the ability of reciprocating pumps to create high pressure and maintain precise control over the flow makes them very valuable. Whether it’s for getting water to your tap or transporting oil through a pipeline, these pumps play an important role in our everyday lives.

You May Also Visit It!

Forging Process | Metal Becomes Tools and Parts – Easy Explanation

History of Nickel | From Ancient Coins to Modern Technology

Metal Does a Magnet Not Stick To | Uses and Types

Physical Properties Are Shared by Most Metals

Advantages and Disadvantages of Reciprocating Pumps

Advantages of Reciprocating Pumps

| Advantages |

|---|

|

Disadvantages of Reciprocating Pumps

| Disadvantages |

|---|

|

Bonus Point

Here are some bonus points about reciprocating pumps that highlight their unique features and interesting facts:

- Energy Efficiency: Reciprocating pumps are often more energy-efficient than other types of pumps, especially when moving high-viscosity liquids. Their ability to create high pressures with relatively low energy consumption makes them a preferred choice in many applications.

- Self-Priming Capabilities: Some models of reciprocating pumps have self-priming capabilities, which means they can remove air from the suction line to start pumping without needing external help. This feature can save time and reduce the risk of pump damage.

- Wide Range of Applications: Beyond industrial uses, reciprocating pumps are also used in residential settings for tasks like providing water pressure in homes or for irrigation systems. Their versatility makes them suitable for many different environments.

- Technology Advancements: With advancements in technology, modern reciprocating pumps can include smart controls that monitor flow rates and pressures, helping to optimize performance and alert users to maintenance needs.

- Environmental Impact: Using reciprocating pumps in certain applications can reduce environmental impacts. For example, they can be used in wastewater treatment processes to help manage and clean water, contributing to environmental protection efforts.

Conclusion

Reciprocating pumps are essential devices that help move liquids efficiently in various industries. They work by using a piston to create pressure, allowing them to handle different types of fluids, including thick and viscous liquids.

While they offer advantages like high pressure and precise flow a control, they also require regular maintenance and may have limitations such as pulsating flow. Understandin how they function and where they are used can help in choosing the right pump for specific needs.

You May Also Visit It!

Magnetic Materials | What Materials Are Attracted By Magnets – Benefits

Yield Strength of Metals: Types, Uses and Clear and Simple Overview

Heat Treating Steel | Key Temperatures for Hardening, Types and Uses

1075 or 1095 Steel | Find the Best Steel for Your Knife

Aluminium Metal, Types, Uses, Properties and Rust Aluminium

Please Write Your Comments