Metals Machinery

Updated: 28 Jul 2025

295

Metals machinery means the tools and machines used to cut, shape, join, or polish metal. These machines help turn strong metals into useful things like cars, buildings, and even tiny parts inside phones. Without the right metals machinery, working with metal can be slow, messy, and even dangerous. But the good news? With the proper tools, anyone can learn to work with metal safely and easily.

Metalworking machines are found in small workshops and giant factories. Some machines are small and can sit on a table. Others are big and can fill an entire room. These machines make work easier, faster, and safer.

What is Metals Machinery?

Metals machinery means machines and tools that help people work with metal. These machines cut, shape, join, and finish metal pieces. Without metals machinery, making things like cars, tools, or buildings would be very hard.

There are many types of metals machinery. Some are big and used in factories. Others are small and used at home or in school workshops. These machines help make metal smooth, curved, flat, or shiny—depending on what’s needed.

For example, a metal cutting tool slices large sheets of metal into smaller parts. A press brake machine bends metal to form corners. A welding machine joins two pieces of metal together. All these machines work together to turn plain metal into useful things.

Using metalworking machines makes the job faster, easier, and safer. People who build cars, airplanes, or even small tools use metals machinery every day. Whether someone is a beginner or a pro, these machines are a big help.

Types of Metal Machinery

There are many types of metals machinery, and each one has a special job. Some machines cut metal, some shape it, and others join or finish it. Let’s take a closer look at the most common kinds of metalworking machines used in workshops and factories. Here are 24 Types of Metal Machines:

- Milling machine

- Drilling machines

- Grinding machines

- Polishing Machine

- Broaching machines

- Press brake Machines

- Lathe

- Bending machine

- Shearing machines

- CNC lathes

- Hobbing machine

- Planer

- Saws

- Presses

- Laser cutters

- Plasma Cutter

- Shaper

- Cnc waterjets

- Hydraulic Shearing Machine

- Rolling Machine

- Forging Hammer

- Welders

- Riveting Machine

- Sandblaster

Let’s explain each types of metal machines:-

1. Milling Machine

A milling machine removes metal with a spinning tool. It cuts flat surfaces, slots, or shapes. People use it to make engine parts or machine parts.

2. Drilling Machines

These machines make round holes in metal. They are common in workshops and factories. Drilling is used to prepare metal for screws or bolts.

3. Grinding Machines

Grinding machines smooth out rough metal. They can also sharpen tools. They are useful after cutting or welding metal parts.

4. Polishing Machine

A polishing machine makes metal surfaces shiny. It’s great for finishing work like sinks or tools that need to look good.

5. Broaching Machines

These machines cut complex shapes or holes with special tools. They are often used to make gears or keyways.

6. Press Brake Machines

Press brake machines bend sheet metal into angles. People use them to make boxes, doors, or frames.

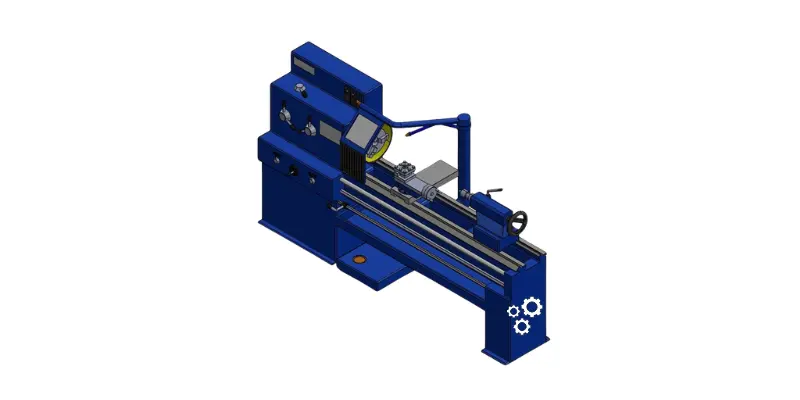

7. Lathe Metal Machines

A lathe spins metal while a sharp tool shapes it. It’s used to make round items like pipes or rings.

8. Bending Metal Machine

This machine bends metal without cutting it. It’s used in making furniture, pipes, and construction parts.

9. Shearing Metal Machines

These work like big scissors to cut sheet metal in straight lines. Factories use them to cut metal before shaping it.

10. CNC Lathes Metal Machine

CNC lathes are computer-controlled lathes. They cut, shape, and smooth metal with high accuracy.

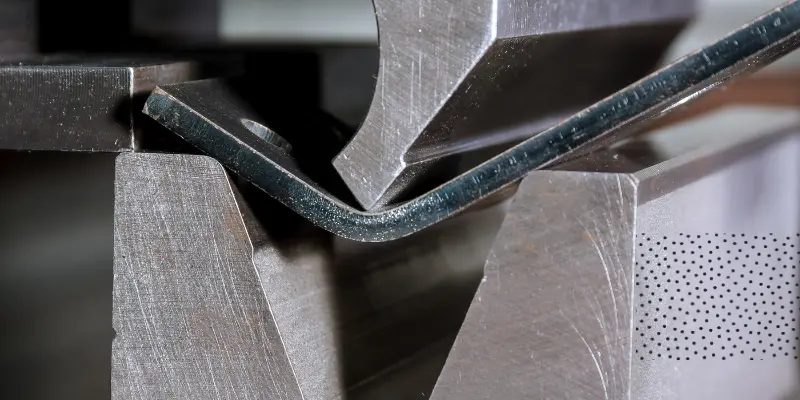

11. Hobbing Metal Machine

Hobbing machines make gears. They cut teeth into round metal pieces to make them turn with other gears.

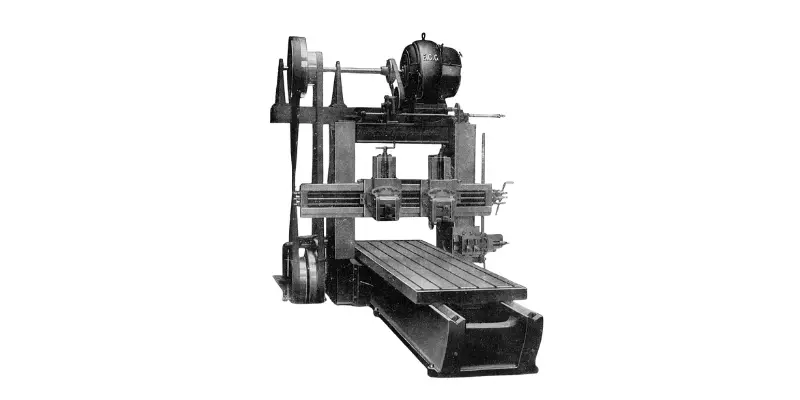

12. Planer Metal Machine

A planer makes metal flat and even. It works well on large metal surfaces like machine beds.

13. Saws Metal Machine

Saws cut metal bars, rods, and sheets. There are different saws like band saws or circular saws for metal.

14. Presses Metal Machine

Press machines push metal into shapes using heavy force. They are used for punching holes or stamping patterns.

15. Laser Cutters Metal Machine

Laser cutters use light to slice through metal. They are fast and very precise, often used in high-tech industries.

16. Plasma Cutter Metal Machine

A plasma cutter uses hot gas to cut thick metal. It’s good for cutting steel and aluminum.

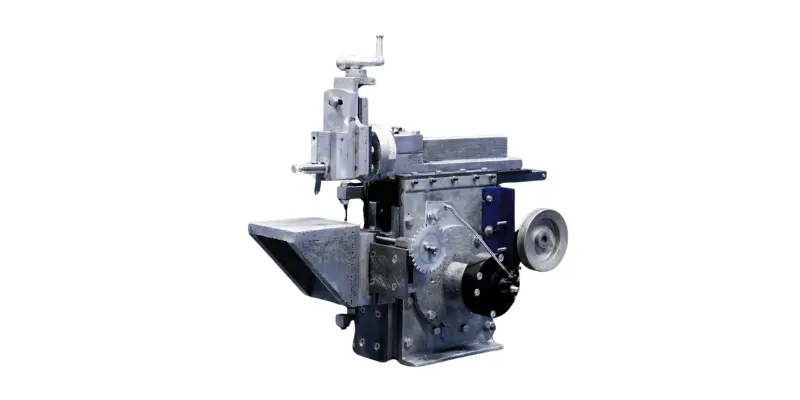

17. Shaper Metal Machine

A shaper moves a cutting tool back and forth over metal. It creates flat or angled surfaces.

18. CNC Waterjets Metal Machine

These machines use water mixed with sand to cut metal. They are cool and don’t heat up the metal.

19. Hydraulic Shearing Metal Machine

This machine uses hydraulic power to cut metal sheets. It’s powerful and used in large factories.

20. Rolling Metal Machine

Rolling machines squeeze metal between rollers. This makes flat sheets or long round pieces like pipes.

21. Forging Hammer Metal Machine

A forging hammer hits hot metal to shape it. It’s used to make strong parts like tools or engine parts.

22. Welders Metal Machine

Welding machines join metal pieces by melting their edges. Welders are used in buildings, cars, and ships.

23. Riveting Metal Machine

Riveting machines join metal using metal pins called rivets. These are common in airplanes and bridges.

24. Sandblaster Metal Machine

A sandblaster cleans metal using air and tiny sand particles. It removes rust and old paint.

Uses of Metal Machinery

Have you ever looked at a car, a building, or a big ship and wondered how they were made? A big part of the answer is metal machinery! These powerful machines help shape metal into useful things we see and use every day. From tiny tools to huge bridges, metal machinery plays a key role in building and fixing many important things around us. Here are some uses of metal machinery, which are included:

- Factories

- Workshops

- Construction

- Shipbuilding

- Tool Making

- Medical

- Repairs

- Invention and Prototypes

- Shaping

- Cutting

- Forming

- Finishing

- Aerospace

- Automotive

- Manufacturing

Safety While Using Metal Machines

Working with metals machinery can be exciting, but safety should always come first. These machines are strong and fast. They can cut, bend, or heat metal in seconds. That’s why it’s important to be careful and use the right safety steps every time. Working with metal machines is helpful but also dangerous if you’re not careful. Here are simple safety tips everyone should follow:

- Always wear PPE: Use personal protective equipment like gloves, glasses, and earplugs.

- Wear protective gear: Suits, helmets, and shields help keep your body safe.

- Safety glasses: Always protect your eyes from sparks or flying metal pieces.

- Use a respirator: Wear one if you’re working in dusty or smoky areas.

- Gloves: Wear the right gloves to protect your hands from sharp or hot surfaces.

- Keep your workspace clean: A clean space helps avoid slips and accidents.

- Follow proper lifting procedures: Use your legs, not your back, when lifting heavy items.

- Know the machine: Learn how each machine works before using it.

- Check tools before use: Make sure your tools are not broken or damaged.

- Conduct regular tool inspections: Always double-check tools for safety.

- Follow safety instructions: Read the manual and follow all the safety signs.

- Implement safety rules: Use rules and signs to remind everyone of safe behavior.

- Mind your hands: Keep fingers away from moving parts and sharp tools.

- Handling products safely: Use tongs, clamps, or holders instead of your hands when possible.

- Check all covers and safety enhancements: Don’t use machines without guards or shields.

- Ensure adequate ventilation: Work in open areas to avoid fumes or dust.

- Tool usage: Use the right tool for the right job. Don’t force tools to do something they are not made for.

- Maintain machines and equipment: Keep machines clean and working properly.

- Perform regular maintenance: Fix small problems before they turn into big ones.

- Follow machine safety guidelines: Every machine has its own rules stick to them.

Small vs. Big Metal Machines

Have you ever wondered how strong metals turn into cars, buildings, or cool machines? It all happens with the help of metal machinery! These machines are like smart tools that help people cut, bend, shape, or join metal. Whether it’s a big machine in a factory or a small one in a workshop, each one plays an important role in making the things we use every day.

Small Metal Machines

Small metal machines are tools that are easy to carry or place on a workbench. They are used for simple jobs at home, school, or small workshops.

- Examples:

- Handheld drill

- Tabletop lathe

- Mini welding machine

- Portable grinder

- DIY metal cutter

These machines are great for students, hobbyists, or beginners. They help you learn metalworking safely.

Big Metal Machines

Big metal machines are heavy-duty machines used in factories and industries. They handle large metal parts and do tough jobs that small tools can’t.

- Examples:

- CNC metalworking machine

- Industrial press brake

- Hydraulic shearing machine

- Forging hammer

- Rolling machine

Big machines do the heavy work. They are not for beginners and need trained workers.

Advantages and Disadvantages of Metal Machinery

Metal machinery helps shape, cut, and join metals to make all kinds of things like cars, bridges, and tools. These machines can do hard jobs quickly and make strong, useful items. But like everything, metal machines also have some good sides and some not-so-good sides.

| Advantages of Metal Machinery |

|---|

|

| Disadvantages of Metal Machinery |

|---|

|

Common FAQs About Metal Machinery

Many people have questions about metal machinery, especially when they are new to metalworking. Below are some common questions and easy-to-understand answers that can help beginners.

What is metal machinery used for?

Metal machinery is used to cut, bend, shape, or join metal parts. It helps make things like cars, buildings, and tools.

Is it safe to use metal machines?

Yes, it’s safe if you follow safety rules like wearing gloves, goggles, and using the machine properly.

What’s the best metal machine for beginners?

Small tools like handheld drills, grinders, or mini welding machines are good for beginners.

Can computers control metal machines?

Yes! CNC machines use computers to make cuts and shapes very accurately.

Are all metal machines big and heavy?

No. Some are small enough to fit on a table and are great for home or school use.

Do I need special training to use metal machines?

For big machines, yes. But small tools can be learned with practice and adult help.

Can I use metal machines at home?

Yes, but use only safe, small machines and always wear safety gear.

What kinds of metals can these machines work with?

They can shape many metals like steel, aluminum, copper, brass, and more.

Do metal machines need electricity?

Most do, especially big ones. Some small ones can run on batteries or hand power.

How can I learn more about metal machinery?

Start by reading guides like this, watching videos, or asking a teacher or expert.

Conclusion

Metals machinery makes it possible to build the world around us. From tiny phones to tall buildings, everything needs the help of metalworking machines. Whether you are working at home or in a factory, these machines make cutting, shaping, joining, and finishing metal easier.

People use sheet metal tools, CNC metal tools, and other metal workshop machines to turn plain metal into amazing things. By learning how to use these tools safely, even beginners can create useful and fun metal projects.

Please Write Your Comments