Different Types of Steel bars Used in Construction

Updated: 09 Feb 2026

116

Steel bars serve as the primary skeleton for every modern structure. Concrete alone cannot resist heavy pulling forces. Steel provides the necessary tensile strength to prevent collapses. Choosing the right material ensures safety and long-term durability. This guide explores the various types of steel bars used today.

Understanding Reinforcement Steel Bars (Rebars)

Reinforcement bars, known as rebars, are the most common steel components. These bars absorb tension that concrete cannot handle alone. Engineers rely on them to prevent structural cracking under pressure. You will find rebars in bridges and high-rise buildings.

Mild Steel Plain Bars

Mild steel bars have a smooth surface without any ribs. They do not bond as tightly with concrete as deformed bars. Consequently, builders usually reserve them for small-scale projects. They are very ductile and easy to manipulate. Most contractors use them for road pavements or expansion joints.

Deformed Steel Bars

Deformed bars feature ribs or lugs on their outer surface. These patterns increase the surface area for a better bond. This mechanical grip reduces the risk of steel slipping. Because of this, they are the standard for heavy-duty builds. You can achieve great structural integrity with these bars.

Technical Comparison of Common Steel Grades

The following table breaks down the primary steel grades used in the industry. These classifications help engineers determine the load-bearing limits of a structure.

| Steel Grade | Yield Strength | Primary Use Case | Key Benefit |

| Fe 415 | 415 N/sq.mm | Small homes | High flexibility |

| Fe 500 | 500 N/sq.mm | High-rise buildings | Best balance of cost/strength |

| Fe 550 | 550 N/sq.mm | Coastal structures | Enhanced load capacity |

| Fe 600 | 600 N/sq.mm | Massive infrastructure | Maximum structural density |

Comparing Material Properties: TMT vs. Forged vs. Mild Steel

Choosing the right bar depends on the specific mechanical requirements of your build. Each manufacturing process creates different internal characteristics.

1. TMT (Thermo-Mechanically Treated) Bars

TMT bars are standard for general reinforcement. They feature a unique “hard-soft” structure. The outer layer provides high strength while the inner core stays ductile. This combination makes them perfect for resisting earthquake shocks.

2. Forged Steel Bars

Forged bars offer superior grain refinement. This process eliminates internal gas pockets and voids. Because of this, they provide much higher impact resistance than standard rolled steel. When your project demands extreme durability, a Forged Steel Bar Manufacturer – Dajin Metal can provide bars with specialized mechanical properties. These are often used in heavy industrial foundations and machinery supports.

3. Mild Steel Bars

Mild steel is the most basic form of construction steel. It contains a low carbon content, which makes it very easy to weld. However, it lacks the high tensile strength of TMT or forged options. You should use it primarily for secondary structural elements.

Critical Selection Criteria for Project Managers

When you order steel, you must look beyond the price per ton. High-quality steel ensures the safety of the occupants for decades.

- Rib Consistency: Ensure deformed bars have uniform ribbing for concrete bonding.

- Surface Quality: Check for excessive pitting or deep rust before use.

- Certification: Always request test certificates from the manufacturer.

- Bending Radius: Quality steel should bend 180 degrees without showing cracks.

- Chemical Balance: Low sulfur and phosphorus levels prevent metal brittleness.

Environmental Considerations

If you build near the sea, salt air will attack your steel. In these cases, standard TMT bars may fail within a few years. You should invest in galvanized or epoxy-coated bars for these environments. These specialized coatings stop the oxidation process before it starts.

Summary of Steel Types in Construction

Modern buildings require a mix of different steel types to remain stable. You might use TMT bars for the main columns and forged steel for high-stress anchor points. By sourcing from a reliable Forged Steel Bar Manufacturer – Dajin Metal, you guarantee that every component meets international safety codes. Never compromise on the quality of your reinforcement steel. It is the only thing keeping your concrete from failing under pressure.

Key Types of High-Strength Steel Bars

Advancements in metallurgy have created much stronger steel variants. These options allow for thinner columns and wider open spans.

Cold Twisted Deformed (CTD) Bars

Workers produce CTD bars by stretching steel at room temperature. This process increases the yield strength by a large margin. However, they are becoming less popular due to corrosion issues. Many modern building codes now prefer more advanced alternatives.

Thermo-Mechanically Treated (TMT) Bars

TMT bars represent the gold standard in the current industry. Manufacturers use a specialized heat treatment to create them. The result is a hard outer skin and soft core. These bars offer excellent weldability and high fire resistance. Most engineers recommend them for zones with high seismic activity.

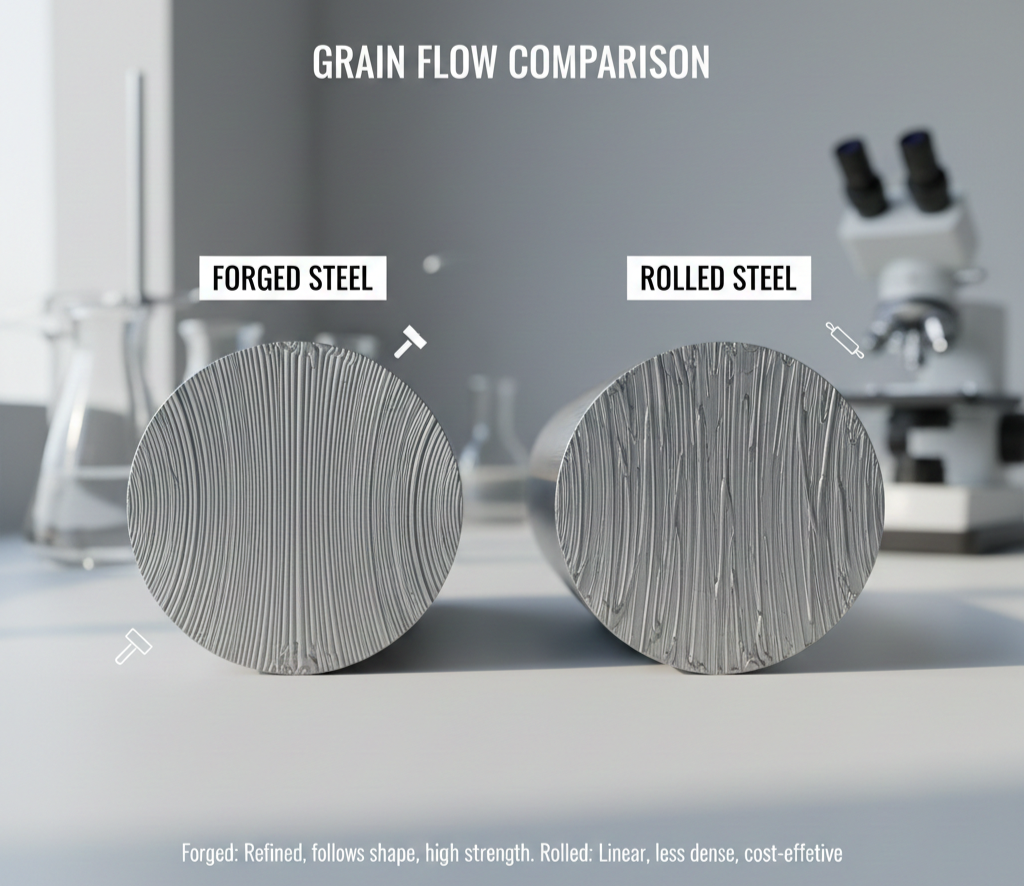

The Importance of Manufacturing Methods

The way steel is shaped changes its internal grain structure. This affects how the metal reacts under extreme stress or impact.

The Benefits of Forging Processes

Forging involves using compressive forces to shape the metal. This method refines the grain and increases overall toughness. Many heavy-duty industrial projects require this level of material density. If you need high-performance components, sourcing from a reputable Forged Steel Bar Manufacturer – Dajin Metal ensures the highest structural standards. Their products withstand much higher fatigue than standard cast steel.

Hot Rolled Steel Applications

Hot rolling involves passing steel through rollers at high heat. This method is fast and cost-effective for mass production. It produces standard shapes like I-beams and long rebars. Most general construction projects rely on these hot-rolled products.

Specialized Steel Bars for Harsh Environments

Some projects require extra protection against environmental factors. Standard steel may rust quickly in coastal or industrial zones.

Epoxy-Coated Steel Bars

Epoxy coating acts as a barrier against moisture and salt. These bars are vital for bridges near the ocean. The coating prevents the chemical process of rusting effectively. However, you must handle them carefully to avoid scratches.

Galvanized Steel Bars

Galvanized bars undergo a protective zinc-dipping process. This creates a sacrificial layer for the underlying steel. They are more durable than epoxy-coated bars in rough settings. While they cost more, they extend the life of the building.

Stainless Steel Rebars

Stainless steel is the premium choice for total longevity. It resists corrosion naturally without needing any extra coatings. Engineers use these in infrastructure meant to last for centuries. The high initial cost is offset by zero maintenance needs.

Technical Classifications of Steel Strength

Steel bars are categorized by their specific yield strength. This rating tells engineers how much stress the bar survives.

- Fe 415: Used mainly for small residential buildings.

- Fe 500: The most versatile grade for commercial work.

- Fe 550: Designed for heavy-duty industrial foundations.

- Fe 600: Reserved for massive bridges and towers.

Pro Tip: Always check the “Fe” grade before pouring concrete. Higher numbers mean the steel handles much more weight.

Factors to Consider When Selecting Steel

Selecting the wrong material can lead to dangerous structural failure. You must evaluate several variables before placing your order.

- Tensile Strength: Ensure the steel handles the calculated loads.

- Ductility: The steel must bend without snapping during earthquakes.

- Corrosion Resistance: Consider the humidity levels of your site.

- Weldability: Check if the bars join easily on-site.

- Thermal Stability: The steel must maintain its shape during heat.

Why Material Quality Impacts Building Safety

Low-quality steel often contains high levels of phosphorus and sulfur. These impurities make the metal brittle and prone to breakage. High-quality bars ensure the concrete remains under constant compression. Investing in premium materials saves money on future structural repairs.

Furthermore, proper storage on-site prevents premature surface rusting. Always keep your steel bars off the wet ground. Use waterproof sheets to protect them from heavy rain. Even the best TMT bars can degrade if left in mud.

Conclusion

Modern construction relies on a diverse range of steel products. From TMT bars to stainless steel, every type serves a role. Understanding these differences helps you build safer and better structures. For specialized needs, partnering with a professional Forged Steel Bar Manufacturer – Dajin Metal, provides the necessary material strength. Quality steel is the ultimate insurance for any construction project.

Please Write Your Comments