Why Ferritic Iron Matters | Key Benefits and Applications

Updated: 09 Nov 2024

486

Introduction

Ferritic iron, a unique type of iron known for its magnetic properties and durability, plays a vital role in many industries. Unlike other forms of iron, ferritic iron has a body-centered cubic structure that gives it excellent corrosion resistance and makes it especially useful in applications where strength and stability are essential. Found in everything from car parts to construction materials, ferritic iron combines affordability with performance, making it a popular choice in both everyday and high-demand settings.

In this article, we’ll explore what makes ferritic iron stand out, its key properties, and why its such a valuable material across various industries. Whether you’re a student, professional, or simply curious about metals, this guide will help you understand the important qualities and applications of ferritic iron.

What Is Ferritic Iron?

Ferritic iron is a special type of iron that has a strong and sturdy structure. Imagine it as iron with an extra boost, making it less likely to rust and better at handling heat. This type of iron is commonly used in things like car parts, buildings, and even some kitchen tools, because it’s tough and doesn’t break down easily.

One cool thing about ferritic iron is that it’s magnetic, which means it can stick to other metals. This property is really useful in making certain machines and tools. When you see ferritic iron in everyday items, it’s because it helps them stay strong and work well for a long time.

You May Also Visit It!

Spray Arc Welding – Step by Step Guide – Need Metals

Pre Coat Metal | Define Complete Guide- Need Metals

Mcelroy Metals – Types, Uses And Properties – Need Metals

Will Magnets Stick to Stainless Steel Refrigerator – Complete Guide

Why is Ferritic Iron Important?

Ferritic iron is widely used in various industries because it has special qualities that make it incredibly useful. Here’s why ferritic iron matters:

1. Strong and Durable

- Ferritic iron is very strong and can withstand a lot of pressure.

- It does not easily break or bend, making it perfect for building strong structures.

2. Resistant to Rust and Corrosion

- Unlike regular iron, ferritic iron doesn’t rust easily.

- This resistance to corrosion helps it last longer, especially in outdoor environments or in places with moisture.

3. High Heat Resistance

- Ferritic iron can handle high temperatures without losing its strength.

- This makes it ideal for parts that are exposed to heat, like car exhaust systems and kitchen appliances.

4. Magnetic Properties

- Ferritic iron is magnetic, which means it can stick to other metals.

- This is important in making magnetic tools, motors, and certain electronics.

5. Cost-Effective

- Ferritic iron is generally less expensive than other types of metal.

- Its affordability and durability make it a practical choice for many everyday products.

Ferritic iron is important because it combines strength, rust resistance, and affordability. These qualities make it essential for building, manufacturing, and creating products that last.

Ferritic Iron vs. Other Types of Iron

There are different types of iron, and each one has its own special qualities. Lets look at how ferritic iron compares to some other types of iron.

1. Ferritic Iron

- Strong and Resists Rust: Ferritic iron is strong and doesn’t rust easily, which makes it good for things that need to last a long time.

- Handles Heat Well: It can withstand high temperatures without melting or breaking down, so it’s used in hot places like car engines.

- Magnetic: Ferritic iron is magnetic, which is useful for making things that need to stick to magnets.

2. Austenitic Iron (or Austenitic Steel)

- Very Rust-Resistant: Austenitic iron does not rust at all, even more than ferritic iron, so it’s often used in kitchen items like sinks and cutlery.

- Not Magnetic: Unlike ferritic iron, austenitic iron is not magnetic, so it doesn’t stick to magnets.

- Flexible but Softer: Its easier to bend and shape than ferritic iron, but it’s not as strong.

3. Martensitic Iron (or Martensitic Steel)

- Very Hard and Strong: Martensitic iron is extremely strong and hard, which makes it great for things like knives and scissors.

- Rusts More Easily: Unlike ferritic iron, it rusts more easily, so it needs to be coated or taken care of.

- Slightly Magnetic: Martensitic iron can be magnetic but not as strongly as ferritic iron.

Applications of Ferritic Iron

Ferritic iron is used in many different things we see and use every day! Its special qualities, like strength and rust resistance, make it useful in lots of ways. Here are some of the main things ferritic iron is used for:

1. Car Parts

- Ferritic iron is often used to make parts of cars, like exhaust systems, because it can handle high heat and doesn’t rust easily.

- This helps cars last longer and work better in different weather conditions.

2. Kitchen Appliances

- Things like ovens, stoves, and fridges often use ferritic iron because it’s strong and can handle heat well.

- Its rust-resistant quality makes it perfect for kitchen tools that need to stay clean and safe.

3. Construction Materials

- Ferritic iron is also used to build strong structures like bridges, buildings, and fences.

- It’s strong and tough, so it can hold up heavy weights without bending or breaking.

4. Industrial Equipment

- In factories, ferritic iron is used to make machines that need to stay strong and work in hot environments.

- It helps keep the machines working well for a long time.

5. Household Items

- Some household items, like washing machines and dishwashers, use ferritic iron parts because they need to handle water without rusting.

- This helps the appliances last longer and work better over time.

Ferritic iron is everywhere. From cars and buildings to kitchen tools and household machines, it helps make our everyday things stronger and longer-lasting.

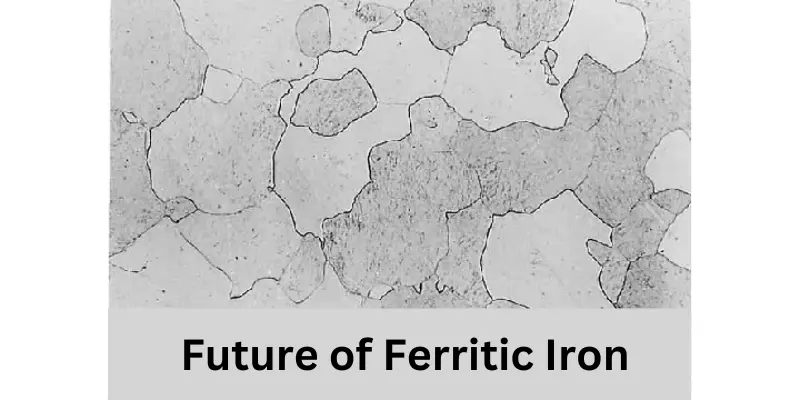

Future of Ferritic Iron

Ferritic iron has been used for a long time, and scientists are still finding new ways to make it even better! Here are some ways ferritic iron might be used in the future:

1. New, Stronger Buildings

- Ferritic iron could help create buildings and bridges that are stronger and last longer.

- As engineers learn more, they can make even better materials for building safer cities.

2. Eco-Friendly Cars and Machines

- Since ferritic iron is good with high heat, it can be used in cars that produce less pollution.

- In the future, ferritic iron might help make eco-friendly cars and machines that protect the planet.

3. Better Kitchen and Home Appliances

- Ferritic iron might be improved to make home appliances like ovens and fridges even tougher and longer-lasting.

- This means less waste, since people wouldn’t need to replace their appliances as often.

4. New Uses in Space Technology

- Scientists are exploring how ferritic iron could be used in rockets and space equipment because of its strength and heat resistance.

- This could help astronauts stay safe and explore space even more!

5. More Recycling Opportunities

- As we work to protect the planet, ferritic iron can be recycled and reused in new products.

- Recycling ferritic iron will help save natural resources and reduce waste in the future.

Ferritic iron has an exciting future! With new ideas and technologies, it can help build a better, safer world from stronger buildings to eco-friendly cars and even space exploration.

You May Also Visit It!

Forging Process | Metal Becomes Tools and Parts – Easy Explanation

History of Nickel | From Ancient Coins to Modern Technology

Metal Does a Magnet Not Stick To | Uses and Types

Physical Properties Are Shared by Most Metals

Advantages and Disadvantages of Ferritic Iron

Just like everything else, ferritic iron has good points and some not-so-good points.

Advantages of Ferritic Iron

| Advantages |

|---|

|

Disadvantages of Ferritic Iron

| Disadvantages |

|---|

|

Ferritic iron has many great qualities, like strength and heat resistance, but there are some situations where other materials might work better.

Frequently Asked Questions about Ferritic Iron

1. What is ferritic iron?

Ferritic iron is a type of iron that is strong, doesn’t rust easily, and can handle high heat. It’s used in things like car parts, kitchen appliances, and buildings because it’s durable.

2. Where is ferritic iron used?

Ferritic iron is used in many places. You’ll find it in car engines, bridges, ovens, and even washing machines. Its strength and rust resistance make it perfect for items that need to last.

3. Why does not ferritic iron rust easily?

Ferritic iron has a special structure that makes it more resistant to rust than regular iron. This means it can handle moisture better and lasts longer in wet environments.

4. Is ferritic iron magnetic?

Yes, ferritic iron is magnetic! This is why it’s often used in magnetic tools and certain machines that need magnetism to work.

5. What makes ferritic iron different from other types of iron?

Ferritic iron is different because it’s stronger and more rust-resistant than regular iron. It can handle high heat better, but it’s not as flexible or rust-proof as some types of stainless steel.

6. Can ferritic iron be recycled?

Yes, ferritic iron can be recycled! Recycling it is good for the environment because it helps reduce waste and saves resources.

7. Is ferritic iron safe to use in the kitchen?

Absolutely. Ferritic iron is used in things like stoves, ovens, and other appliances because it’s strong, resists rust, and handles heat well. It’s a great choice for kitchen items.

8. What are the main advantages of ferritic iron?

Ferritic iron is strong, handles high temperatures, doesn’t rust easily, and is magnetic. These qualities make it very useful in lots of products.

9. Are there any disadvantages of ferritic iron?

Yes, ferritic iron can crack under extreme stress, isn’t as flexible as some other metals, and doesn’t perform well in very cold temperatures. But in most cases, it’s still a great material!

10. Will ferritic iron be used in the future?

Definitely. Scientists are finding new ways to make ferritic iron even better, so it could be used in eco-friendly cars, space equipment, and stronger buildings in the future.

These FAQs help explain what makes ferritic iron special and why it’s used in so many things around us.

Conclusion

Ferritic iron is a strong, rust-resistant metal thats perfect for many everyday items, like car parts, kitchen appliances, and buildings. Its ability to handle heat and resist corrosion makes it very useful in tough environments.

While its not as flexible as some other metals, its still an important material for things that need to last. As scientists continue to improve ferritic iron, it will likely be used even more in the future to make our world stronger and more eco-friendly.

Bonus Points about Ferritic Iron

Here are some extra cool facts about ferritic iron.

- Great for High-Temperature Jobs: Ferritic iron can handle really hot conditions, which makes it perfect for things like engines and exhaust systems in cars.

- Eco-Friendly: Because ferritic iron can be recycled, it helps reduce waste and conserve natural resources, making it an eco-friendly material.

- Used in Magnets: Since ferritic iron is magnetic, it’s often used to make magnets in things like motors and other machines.

- Long Lifespan: Thanks to its resistance to rust and strength, ferritic iron parts can last a long time, which saves money and reduces the need for replacements.

- Improved Over Time: Scientists and engineers are constantly finding ways to improve ferritic iron, making it even stronger and more useful in more advanced technologies.

These bonus points show just how amazing ferritic iron is and why it plays such an important role in so many industries.

You May Also Visit It!

Magnetic Materials | What Materials Are Attracted By Magnets – Benefits

Yield Strength of Metals: Types, Uses and Clear and Simple Overview

Heat Treating Steel | Key Temperatures for Hardening, Types and Uses

1075 or 1095 Steel | Find the Best Steel for Your Knife

Aluminium Metal, Types, Uses, Properties and Rust Aluminium

Please Write Your Comments