Gauge vs MM | Find Ideal Thickness for Your Next Creation

Updated: 12 Nov 2024

821

Introduction

When it comes to measuring material thickness, understanding gauge vs mm can make a significant difference in your projects. Gauges and millimeters (mm) are both used widely, but each has its own characteristics and applications, especially in fields like metalworking, jewelry-making, and engineering. Gauge numbers can feel a bit confusing, as they represent different thicknesses depending on the material type—steel, aluminum, or even plastic all follow different gauge standards. Millimeters, on the other hand, offer a straightforward metric measurement that many find easier to work with.

In this guide, we’ll walk you through the differences between gauge and mm, how to convert between them, and when each measurement might be the better choice. Whether you’re selecting the right metal sheet for a construction project or choosing wire thickness for jewelry, this knowledge will help you make informed, accurate choices every time.

What is Gauge vs MM?

When we talk about “Gauge vs MM,” we’re looking at two ways to measure the thickness of things, especially metals and wires. Imagine you have a piece of metal or a thick wire. You could measure how thick it is using either gauge or millimeters (mm).

- Gauge: This is a number used to show thickness. The funny thing about gauge is that the bigger the number, the thinner the material. For example, a 20-gauge piece of metal is thinner than a 10-gauge one. Gauge numbers are often used in the United States, especially in crafts and construction.

- Millimeters (mm): Millimeters are a standard unit of length in the metric system. With millimeters, things are measured directly, so a bigger number means thicker material. This measurement is common worldwide and is easy to understand because it’s part of the metric system.

So, when people talk about Gauge vs MM, they are comparing two ways to measure thickness. Each has its use, and knowing both can help you pick the right thickness for different projects.

You May Also Visit It!

Spray Arc Welding – Step by Step Guide – Need Metals

Pre Coat Metal | Define Complete Guide- Need Metals

Mcelroy Metals – Types, Uses And Properties – Need Metals

Will Magnets Stick to Stainless Steel Refrigerator – Complete Guide

Why Is Understanding Gauge vs MM Important?

Understanding the difference between gauge and mm is crucial for a variety of reasons, especially in fields where precise measurements matter. Whether you’re working in construction, metalworking, or even jewelry-making, knowing when and how to use each measurement can make a significant impact on the success of your project.

1. Accurate Material Selection

- Choosing the Right Thickness: Different projects require specific material thicknesses. If you need a strong material for construction, you’ll choose a lower gauge (which means thicker material). If you need something more flexible or lightweight, you’ll opt for a higher gauge (thinner material).

- Avoid Mistakes: Misunderstanding gauge and mm conversions can lead to selecting the wrong material, which may affect the quality or safety of your project.

2. Consistency Across Projects

- Standardization: Different industries use gauge and mm in various ways. Understanding both helps you maintain consistency across projects, especially when working internationally, where mm is often preferred.

- Material Comparison: In some cases, the same material will have different thicknesses depending on whether its measured in gauge or mm. Knowing both allows you to compare options more effectively.

3. Improved Precision

- Metric vs. Imperial: While gauge measurements are often used in the U.S., millimeters are part of the metric system, used worldwide. Being able to work with both systems increases your flexibility when collaborating with others or working on global projects.

- More Accurate Calculations: Using millimeters can provide more precision in measurements, which is especially important when working with small or delicate materials.

4. Better Communication

- Easier Collaboration: If you’re working with teams across different regions, knowing both systems of measurement can make it easier to communicate specifications clearly. It’s especially important when working with international partners who may only use mm.

- Avoiding Confusion: By understanding both methods, you can avoid misunderstandings when reading instructions, blueprints, or specs that use different measurement systems.

The difference between gauge and mm helps you make smarter, more accurate decisions, ensures better communication, and ensures the success of your projects. Whether you’re measuring steel, wire, or another material, this knowledge is key to getting the right fit every time.

Gauge vs. Millimeter: Key Differences

When we compare Gauge vs MM, we’re looking at two different ways to measure the thickness of things. Here’s a simple way to understand the main differences:

1. What They Measure

- Gauge: Gauge is a number used to describe how thick or thin a material is. But here’s the twist: the higher the gauge number, the thinner the material. For example, a 10-gauge piece of metal is thicker than a 20-gauge piece.

- Millimeters (mm): Millimeters are part of the metric system, and they are used to measure things with exact lengths. The bigger the number of millimeters, the thicker the material. For example, a 10 mm piece of metal is thicker than a 5 mm piece.

2. How They Are Used

- Gauge: Gauge is commonly used in countries like the United States, especially for materials like metal sheets, wires, and even nails. It’s used when you want to quickly know how thick or thin a material is without needing to measure it in millimeters.

- Millimeters (mm): Millimeters are used in the metric system, which is the most common way of measuring things around the world (except in the U.S.). Millimeters are more precise because they give exact numbers.

3. How They Relate

- Gauge vs. mm: While both can be used to measure thickness, they don’t always match up perfectly because gauges are often different depending on the type of material. For example, a 10-gauge steel might not be the same thickness as a 10-gauge aluminum. However, millimeters are the same no matter what material you measure. So, using mm gives you a more standard and exact measurement across different materials.

4. Why They Matter

- Gauge is helpful when you don’t need super precise measurements, like when choosing metal for something strong like a fence.

- Millimeters are great for when you need exact measurements, especially in things like building blueprints, electronic devices, or jewelry-making, where precision is important.

By understanding these differences, you can choose the right measurement depending on your project.

Conversion Basics: How to Convert Gauge to mm

Converting from Gauge vs MM can be tricky, but it’s important to know how to do it when you need the right thickness for your project. Here’s a simple guide to understand how the conversion works.

1. Understanding the Conversion

- Gauge numbers measure the thickness of materials, and millimeters (mm) measure the length of an object. Since they are used in different systems (gauge for U.S. and mm for the metric system), we need a way to convert from one to the other.

- The larger the gauge number, the thinner the material is. But with millimeters, a larger number means a thicker material.

2. How to Convert

There is not a simple formula that works for all materials because gauges are different for different types of materials. For example, a steel gauge conversion is different from an aluminum gauge. But in general, here’s how you can do it:

- Find a Conversion Chart: This is the easiest way! These charts show you exactly how each gauge number converts into millimeters. For example, a 10-gauge steel sheet might be 3.4 mm thick, while a 10-gauge aluminum sheet could be 2.59 mm thick.

- Use Online Converters: There are many websites that can automatically convert gauge to mm for you. All you need to do is type in the gauge number and the material, and the site will give you the thickness in millimeters.

3. Example of a Gauge to mm Conversion

- If you have a 12-gauge steel sheet, you can look at a conversion chart and find out that it is 2.77 mm thick.

- If you need to convert 14-gauge aluminum to mm, you can check the chart, and it will show that it’s about 1.98 mm thick.

4. Why Use Conversion Charts or Tools?

- Accuracy: These tools make sure you get the right thickness. If you need to build something and it has to be strong, using the wrong thickness could cause problems. For example, if you accidentally use a thinner material than needed, it might not hold up.

- Convenience: Instead of doing the math yourself, which could get confusing with different materials, using a chart or converter saves you time and effort.

By using conversion charts or online converters, you can easily convert gauge numbers to millimeters and make sure you’re using the right thickness for your project.

Gauge Charts for Common Materials

When you’re working with different types of materials like metal, wire, or sheet metal, it’s important to know how their gauge numbers translate into Gauge vs MM. Here are some common materials and their gauge-to-mm conversions. These charts will help you figure out the thickness of each material based on its gauge number!

1. Steel Gauge Chart

Steel is one of the most common materials that uses gauge numbers. The gauge number tells you how thick the steel is, but remember, the higher the gauge number, the thinner the steel.

| Gauge Number | Thickness (mm) |

| 10 | 3.40 mm |

| 12 | 2.77 mm |

| 14 | 2.03 mm |

| 16 | 1.65 mm |

| 18 | 1.22 mm |

Steel gets thinner as the gauge number increases, so a 10-gauge steel is thicker than 18-gauge steel.

2. Aluminum Gauge Chart

Aluminum is another common material used in many projects, and its gauge numbers work similarly to steel, but with slightly different thicknesses.

| Gauge Number | Gauge Number Thickness (mm) |

| 10 | 2.59 mm |

| 12 | 2.11 mm |

| 14 | 1.63 mm |

| 16 | 1.29 mm |

| 18 | 1.02 mm |

In this chart, you can see that 10-gauge aluminum is thinner than 10-gauge steel.

3. Copper Wire Gauge Chart

Copper wire is often used in electrical projects. The thickness of copper wire is also measured by gauge, but the thickness is much smaller compared to steel or aluminum.

| Gauge Number | Diameter (mm) |

| 10 | 2.59 mm |

| 12 | 2.05 mm |

| 14 | 1.63 mm |

| 16 | 1.29 mm |

| 18 | 1.02 mm |

Here, 18-gauge copper wire is very thin, but it is perfect for many electrical tasks!

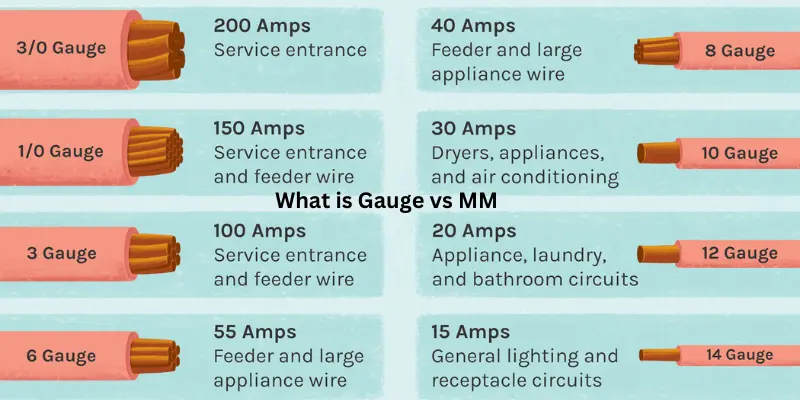

4. Wire Gauge Chart (for Electrical Wires)

For electrical wires, gauge tells you how much electrical current the wire can safely carry. A lower gauge number means a thicker wire, which can carry more current.

| Gauge Number | Diameter (mm) | Current Capacity (Amps) |

| 10 | 2.59 mm | 30-40 amps |

| 12 | 2.05 mm | 20-25 amps |

| 14 | 1.63 mm | 15-20 amps |

| 16 | 1.29 mm | 10-13 amps |

As you can see, the thicker the wire (lower the gauge number), the more electricity it can safely carry.

Why Are Gauge Charts Helpful?

- Easy Reference: Gauge charts help you quickly figure out the right material thickness you need for any project.

- Consistency: If you’re working with the same material in a project, knowing the gauge-to-mm conversion helps you keep your work uniform.

- Precise Measurements: If you need exact measurements, gauge charts make sure you can compare the thicknesses accurately.

When you need to choose the right thickness for your project, use these charts to help guide you. Whether you’re building something out of metal, wire, or copper, you’ll know exactly what gauge number and thickness you need.

How to Select Between Gauge vs MM for Projects

Choosing between gauge and Gauge vs MM for your project can depend on what you’re building and where you’re located. Here’s a simple guide to help you decide which one to use!

1. Consider the Material You’re Using

Different materials use either Gauge vs MM to measure thickness. Here’s what you need to know:

- Metal Sheets: In the U.S., gauge is commonly used for materials like steel and aluminum. For example, if you’re working with steel or copper, you may see gauge numbers used instead of mm.

- Wire: For wires, such as copper wire, you’ll usually see gauge numbers, especially in electrical projects. The lower the gauge number, the thicker the wire.

- General Use: If you’re outside of the U.S., especially in places like Europe, millimeters (mm) are often used for all kinds of measurements, including thickness. If you need more precision, millimeters might be better.

2. Look at the Measurement System You Are Most Comfortable With

- Gauge is often used in the U.S. for measuring thickness in metal and wire. If you’re in the U.S. and your project involves metals or wires, gauge is the way to go.

- Millimeters (mm) are part of the metric system, which is used almost everywhere else in the world. If you need exact measurements, or if you’re working with projects in other countries, mm is probably the better choice.

3. Precision vs. Simplicity

- Millimeters (mm) are usually more precise because they give you exact measurements. For example, if you need something to be exactly 2 mm thick, using mm is the best way to measure it.

- Gauge is helpful when you need a quick estimate but don’t need super exact numbers. It’s great when working on large projects like metalworking, where precise measurements aren’t always necessary.

4. Check the Project Guidelines

- Some projects (like building a fence, working with metal, or crafting jewelry) may give you specific guidelines on whether to use Gauge vs MM. If you’re following instructions, it’s best to follow the recommended system for better results.

5. Use Conversion Charts if You Need Both

- If you come across a project where you need to switch between Gauge vs MM, it’s a good idea to use conversion charts. They’ll help you understand how gauge numbers relate to mm so you can keep your measurements accurate.

6. Choose Based on Your Tools

- Some tools or machines (like sheet metal cutters or wire strippers) are designed to work with either Gauge vs MM measurements. If you’re using a tool that shows gauge numbers, then stick with gauge. But if your tool shows mm, then use millimeters.

You May Also Visit It!

Forging Process | Metal Becomes Tools and Parts – Easy Explanation

History of Nickel | From Ancient Coins to Modern Technology

Metal Does a Magnet Not Stick To | Uses and Types

Physical Properties Are Shared by Most Metals

Advantages and Disadvantages of Using Gauge vs MM

When deciding whether to use gauge or millimeters (mm) for your project, its important to consider the benefits and drawbacks of each measurement system.

Advantages of Using Gauge

| Advantages |

|---|

|

Easier for General Use (Especially in the U.S.)

Simplicity in Common Projects

Consistency in Industry Standards

|

Disadvantages of Using Gauge

| Disadvantages |

|---|

|

Less Precision

Limited International Use

Can Be Confusing for Beginners

|

Advantages of Using Millimeters (mm)

| Advantages |

|---|

|

Precision and Accuracy

Global Standard

Easier for Detailed Projects

|

Disadvantages of Using Millimeters (mm)

| Disadvantages |

|---|

|

Not Always Familiar in the U.S.

Not as Simple for Quick References

Conversions Needed

|

Which One Should You Use?

- Gauge is best for general use and industries where simplicity is key, like metalworking and electrical wiring.

- Millimeters (mm) are better when you need precision, especially for international projects or when working in the metric system.

Each measurement system has its place depending on your project needs. So, choose the one that works best for your material type, location, and project accuracy.

Common FAQs about Gauge vs MM

What is the difference between gauge and millimeters (mm)?

Gauge is a measurement used mainly for materials like metal and wire. It tells you how thick the material is, but it’s not an exact number. The lower the gauge number, the thicker the material. For example, a 10-gauge wire is thicker than a 12-gauge wire.

Millimeters (mm), on the other hand, are part of the metric system and give you an exact measurement. For instance, 1 mm is 1/1000th of a meter, so it’s more precise and easier to measure exactly compared to gauge.

Which one is better to use Gauge vs MM?

It depends on what you’re working with! If you’re in the U.S. and working with metal sheets or wire, you’ll often see gauge used. If you need exact measurements, especially in projects like jewelry making, electronics, or international projects, then millimeters (mm) are the best choice.

How do I convert Gauge vs MM?

Gauge doesn’t directly convert into mm in a simple formula, because it depends on the material. For example, 12-gauge wire is approximately 2.05 mm thick, but the same gauge number might be different for other materials like aluminum or copper. To convert, it’s best to use a gauge-to-mm conversion chart available online or in tool guides.

Why is gauge used for wire and metal measurements?

Gauge is a traditional system that’s been used for a long time in industries like metalworking, jewelry, and electronics. It’s simpler for quick estimates when working with wires or sheets, especially in the U.S. where the gauge system is more common.

Is gauge used outside of the U.S.?

No, the metric system (including millimeters) is used in most countries outside the U.S.. In countries like Europe, Asia, and Australia, mm is the standard, making it easier for international projects to communicate measurements without needing conversions.

Can I use Gauge vs MM together?

Yes! You can use both systems together by converting between them as needed. If you have a gauge number, you can refer to a conversion chart to find the equivalent in mm or vice versa. For example, a 16-gauge steel sheet is about 1.5 mm thick.

Do I need to use a conversion chart?

It’s helpful to use a conversion chart if you’re switching between gauge and mm measurements. This ensures you get the right thickness for your project, especially if you’re working with precise measurements or international standards.

Which measurement system is used for wire thickness?

In the U.S., gauge is commonly used for wire thickness. However, in many other countries, mm is used for more precise wire measurements. Always check if your wire supplier uses gauge or mm to avoid confusion.

Can gauge be confusing?

Yes, gauge can be confusing because different materials have different thicknesses for the same gauge number. Additionally, higher gauge numbers represent thinner materials, which can be counterintuitive, especially if you’re new to it.

How can I know which measurement to use for my project?

It depends on your project. If you’re working with materials that are commonly measured in gauge (like metal or wire), use that system. If you’re working with precise dimensions, or if you are outside of the U.S., mm is usually the better choice. Consider the project guidelines and location of your materials for the best measurement system!

These FAQs should help clarify the key differences and usage of gauge and millimeters (mm) in everyday projects.

Bonus Points on Gauge vs MM

Here are some extra tips to help you understand and work with Gauge vs MM measurements:

1. Keep a Conversion Chart Handy

- A conversion chart is a useful tool when you need to quickly convert between gauge and mm measurements, especially if you work with various materials. A chart will give you a clear comparison for things like wire thickness or sheet metal. For example, you can easily find that 18-gauge wire is roughly 1.02 mm thick. Save a chart on your phone or print one out for quick access!

2. Gauge for Specific Materials

- When working with materials like wire, metal sheets, or jewelry, be aware that gauge numbers can vary based on the material type. For example, the thickness of a 16-gauge copper wire will differ from the thickness of 16-gauge steel. Always check material-specific charts before starting your project.

3. High vs. Low Gauge

- In the gauge system, a lower gauge number means a thicker material, while a higher number means thinner material. So, 10-gauge metal is thicker than 14-gauge metal. This is important to remember because sometimes you might think higher numbers mean more thickness, but that’s the opposite in the gauge system.

4. Gauge Is not Always Linear

- The gauge system isn’t a perfect, linear scale. For example, the difference between 12-gauge and 14-gauge is bigger than the difference between 30-gauge and 32-gauge. So, if you need a very specific thickness, it’s better to refer to mm measurements, where you’ll get exact numbers.

5. Advantages of Using mm in International Projects

- If you plan to work on international projects, or with people who use the metric system, it’s a good idea to switch to millimeters (mm). The metric system is more widely understood across the world, which can make communication and measurements much smoother.

6. Quick Conversion Method

- If you do not have a chart nearby and need to convert gauge to mm, you can use a rough rule: for wire, one way to convert is by using a standard formula. For example, 6-gauge wire is about 4.11 mm thick, and you can estimate other values using similar approximations.

7. Use for Specific Industries

- Some industries prefer one system over the other. Gauge is popular in the U.S. for tasks like electrical work and metalworking, while mm is often used for things like scientific projects, electronics, and machining. Be mindful of the industry standard when starting your project.

By using these bonus tips, you can save time and avoid confusion when dealing with gauge vs. mm measurements in your projects. Whether you’re crafting, building, or designing, understanding the best practices for using these units can help make your work more efficient and accurate.

Conclusion

In the end, understanding the difference between gauge and millimeters (mm) is key for getting the right measurements in your projects. Gauge is commonly used for materials like wire and metal sheets and gives a general idea of thickness, especially in the U.S. Meanwhile, millimeters (mm) offer a more precise and globally recognized measurement.

Depending on your needs, you may choose gauge for quick, industry-specific estimates or mm for more exact measurements. Remember, using the right unit will ensure your project turns out just the way you want it.

You May Also Visit It!

Magnetic Materials | What Materials Are Attracted By Magnets – Benefits

Yield Strength of Metals: Types, Uses and Clear and Simple Overview

Heat Treating Steel | Key Temperatures for Hardening, Types and Uses

1075 or 1095 Steel | Find the Best Steel for Your Knife

Aluminium Metal, Types, Uses, Properties and Rust Aluminium

Please Write Your Comments