Metal Stamping Aluminum | Easy Steps to Understand Metal Stamping

Updated: 19 Oct 2024

553

Have you ever wondered how the metal stamping aluminum parts in cars, toys, or even soda cans are made? One cool way we shape metal is called metal stamping aluminum! Think of it like using a cookie cutter to press out shapes from dough, but instead of dough, we use strong, shiny metal like aluminum.

Aluminum is special because it’s light, doesn’t rust, and can be used to make all kinds of things we see every day. In metal stamping aluminum, machines press down on a flat piece of aluminum and transform it into amazing shapes! It’s fast, fun, and helps create everything from car parts to soda cans. Let’s explore how this fascinating process works.

What is Metal Stamping Aluminum?

Imagine you have a flat piece of clay, and you want to shape it into something cool, like a star or a heart. You would use a mold or a cutter to press down and give the clay its new shape, right? Well, metal stamping aluminum works the same way, but instead of clay, we use aluminum, a shiny, lightweight metal.

Metal Stamping is when we use a special machine to press down on a flat sheet of aluminum and shape it into something useful, like parts for cars, airplanes, or even small gadgets. It’s kind of like using a cookie cutter to cut dough, but much stronger and with metal.

Table of Contents

Why is Metal Stamping Aluminum Important?

Have you ever wondered how cars, airplanes, or even soda cans are made? Well, metal stamping aluminum helps make many of those things! Here are some reasons why it’s so important:

- Makes Things Fast and Easy

- Imagine if you had to cut shapes from metal all by yourself—it would take forever! Metal stamping allows us to make things quickly and perfectly every time. Machines do the stamping, so they can make hundreds of parts super fast!

- Saves Money

- Because stamping can be done quickly, it doesn’t cost as much as making things by hand. This helps people and companies save money, which is important when making lots of products like cars or gadgets.

- Shapes Aluminum into Useful Parts

- Aluminum is a light but strong metal, and stamping helps shape it into all kinds of things we use every day, like car parts, kitchen tools, and even toys. Without metal stamping, it would be really hard to make these things.

- Perfect Shapes Every Time

- When we use metal stamping, we get the same shape again and again. This is important because things like airplane parts or car doors need to be exactly the same size and shape to work properly. Metal stamping makes sure every piece is perfect.

- Helps Build a Better World

- Metal stamping aluminum also helps in making products that are better for the environment. Aluminum is recyclable, which means we can reuse it over and over again without wasting resources. This is good for our planet!

Metal stamping aluminum is super important because it helps us make things quickly, saves money, and creates perfect parts every time. Plus, since aluminum can be recycled, it’s also helping us take care of the Earth. Isn’t that cool?

Choosing the Right Aluminum Alloy for Metal Stamping

When we make cool things out of metal using metal stamping, like parts for cars or airplanes, we need to choose the right type of aluminum. But wait, did you know there are different types of aluminum? These different types are called alloys.

What is an Alloy?

An alloy is when we mix aluminum with other metals to make it stronger, shinier, or easier to shape. Imagine you’re baking a cake. You start with flour (which is like aluminum) but then you add eggs, sugar, and other things to make the cake taste better and hold together. That’s what we do with aluminum!

Why Use Aluminum Alloys for Metal Stamping?

We use aluminum alloys because they can be bent, pressed, and shaped easily, and they don’t break. Also, aluminum alloys are lightweight, which is important when making things like airplanes or bikes.

How Do We Choose the Right Aluminum Alloy?

Choosing the right aluminum alloy for metal stamping depends on what we’re making. Here are some things we think about:

- Strength: Some things, like car parts, need to be really strong so they don’t break easily. We choose an alloy that is tough and can handle pressure without bending.

- Flexibility: If we’re making something that needs to bend or change shape, we pick an aluminum alloy that is flexible. That means it can be bent or twisted without cracking.

- Lightweight: Aluminum is already light, but some alloys are even lighter. We use these when we want to make things that are easy to carry or fly, like parts of an airplane.

- Rust-Proof: Aluminum alloys don’t rust like iron, but we still choose alloys that stay strong in rain or water. This is great for making things like boats or outdoor objects.

Common Aluminum Alloys for Metal Stamping

Here are some examples of alloys that are often used for metal stamping:

- 3003 Alloy: This is a very popular alloy because it’s strong and flexible. It’s often used for food containers, soda cans, and kitchen utensils.

- 5052 Alloy: This one is perfect for things that need to be strong and resistant to rust, like parts of cars or boats.

- 6061 Alloy: This alloy is super strong and is used in things like airplanes, bikes, and big structures.

Fun Fact: No matter which aluminum alloy we choose, it can always be recycled and used again, helping protect the environment!

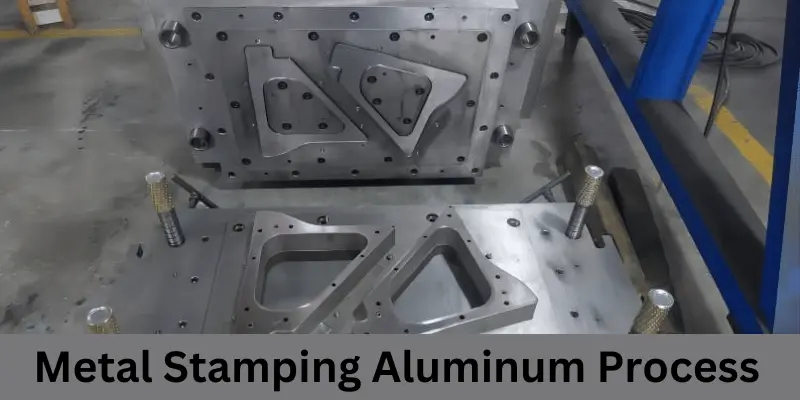

Metal Stamping Aluminum Process

Imagine you have a piece of dough, and you use a cookie cutter to make fun shapes like stars or hearts. The stamping process is very similar, but instead of dough, we use metal, and instead of cookie cutters, we use special tools called dies.

In stamping, a big machine presses down on the metal to shape it into useful things like car parts, toys, or even soda cans. Let’s go through the steps!

Metal Stamping Aluminum Process Work?

- Start with a Flat Metal Sheet

- The first step is to get a flat piece of metal, like aluminum, which is smooth and shiny. It looks like a big, thin sheet, almost like a metal version of paper!

- Set Up the Die

- The next step is to use a tool called a die. This die is like a mold or cookie cutter, shaped like the part we want to make. For example, if we want to make a toy car part, the die will be shaped like that part.

- Press and Shape the Metal

- Now comes the fun part! A machine presses the die onto the metal sheet with a lot of force. This bends, cuts, or shapes the metal into the design of the die, just like how you press down with a cookie cutter to make shapes in dough.

- Repeat to Make More

- Once the first piece is stamped, we can stamp more pieces by repeating the process. This way, we can quickly make many parts that are exactly the same.

- Finishing Touches

- After the metal is stamped, sometimes we need to smooth the edges or polish the surface to make sure the part is perfect and ready to use.

Uses of Metal Stamping Aluminum

Aluminum is a special metal that’s lightweight, shiny, and strong. When we use metal stamping to shape aluminum, we can create lots of useful things! Let’s explore some cool ways aluminum stamping is used:

- Cars and Trucks

- When you see a car or truck, it has many parts made from stamped aluminum. Why? Because aluminum is light, which helps cars go faster and saves fuel. Things like car doors, hoods, and even some engine parts are made using metal stamping.

- Airplanes

- Did you know airplanes are made using aluminum too? Because aluminum is both light and strong, it helps planes fly smoothly without being too heavy. Stamped aluminum parts help build airplane wings, bodies, and even seats!

- Soda Cans

- When you drink a soda or juice, the can it comes in is usually made of aluminum. Metal stamping is used to shape aluminum into the round cans we use. It’s easy to make and can be recycled into new cans later.

- Gadgets and Phones

- Your tablet, phone, or even computer may have parts made from stamped aluminum. Aluminum helps keep gadgets light and cool. Stamped aluminum parts are often used for the covers or cases, protecting all the important stuff inside.

- Cooking Tools

- Ever used a shiny aluminum pan or pot at home? Aluminum metal stamping helps create cookware like baking trays, pans, and even the foil you wrap your sandwiches in. It’s safe to use and heats up quickly, making cooking easier!

- Bikes

- The next time you ride a bike, think about this—many bikes have aluminum parts made through metal stamping! Since aluminum is light, it helps make bikes faster and easier to ride.

- Buildings

- Metal stamping is used to make important aluminum parts for buildings, like windows, doors, and even parts of the roof. Aluminum doesn’t rust, so it’s great for making things that last a long time outdoors.

- Toys

- Some of your toys might have tiny aluminum parts made using metal stamping. Whether it’s a shiny metal car or a cool robot, aluminum helps make toys that are light but still strong!

- Making Sports Equipment

- Aluminum is also used in sports gear, like bicycles and baseball bats. Metal stamping shapes these items to make them strong and ready for action!

Types of Metal Stamping Aluminum

Metal stamping aluminum can be done in different ways, just like how you can use different tools to make crafts. Here are some common types:

- Blanking

- What It Is: This is like cutting out shapes from a piece of paper using scissors. In blanking, we cut a flat piece of aluminum into specific shapes.

- Example: Imagine making a star out of a piece of aluminum!

- Bending

- What It Is: Bending is when we change the shape of aluminum by pushing it to create angles. It’s like bending a piece of cardboard to make it stand up.

- Example: Think of making a letter “L” out of a flat piece of metal!

- Forming

- What It Is: Forming is when we shape the aluminum into curves or rounded shapes. It’s like molding clay into a bowl.

- Example: Picture making a rounded cap for a bottle!

- Deep Drawing

- What It Is: In deep drawing, we pull a flat piece of aluminum down into a mold to make it deeper. It’s like pressing a cookie cutter down into dough to create a deeper cookie shape.

- Example: Imagine making a deep cup shape out of a flat piece of aluminum!

- Piercing

- What It Is: Piercing is when we make holes in aluminum. It’s similar to poking holes in paper with a hole punch.

- Example: Think about making holes for screws in a metal part!

- Stretch Forming

- What It Is: This type stretches the aluminum to make it longer or wider. It’s like stretching a piece of taffy to make it thinner.

- Example: Imagine making a long, flat strip of aluminum!

- Embossing

- What It Is: Embossing is when we create designs or patterns on the aluminum by pressing down. It’s like pressing a stamp onto clay.

- Example: Think of making fun shapes, like flowers or stars, on the metal!

- Notching

- What It Is: Notching means cutting small pieces out of the aluminum to create notches or grooves. It’s like cutting a small triangle out of a piece of paper.

- Example: Imagine making little notches in a metal part to help it fit with something else!

- Coining

- What It Is: Coining is a precise way of stamping details into the aluminum. It’s like making a perfect design on a coin!

- Example: Think of making a shiny coin with a special picture on it!

- Assembly Stamping

- What It Is: This involves putting together different stamped parts to create a final product. It’s like assembling a puzzle!

- Example: Imagine putting together pieces of a toy car made from stamped aluminum!

Advantages and Disadvantages of Metal Stamping Aluminum

Metal stamping aluminum has many benefits, like making strong parts quickly and saving money. However, it also has some downsides, like needing special machines and sometimes wasting materials.

Benefits of Metal Stamping Aluminum

| Pros of Metal Stamping Aluminium |

|---|

|

Drawback of Metal Stamping Aluminum

| Cons of Metal Stamping Aluminium |

|---|

|

Conclusion

Metal stamping aluminum is a really cool process that helps us create many things we use every day, like cars, toys, and even soda cans! Just like using cookie cutters to make fun shapes from dough, metal stamping uses special tools to shape and cut aluminum into amazing designs.

We learned that aluminum is a lightweight and strong metal that doesn’t rust, which makes it perfect for so many products. The stamping process is quick and efficient, allowing us to make lots of the same parts in a short time. Plus, aluminum can be recycled, which is great for our planet!

So, next time you see a shiny aluminum can or a cool toy, remember the fun journey it went through with metal stamping! It’s a fantastic example of how creativity and technology work together to make our lives better.

Please Write Your Comments