What Is Metallurgical | Step by Step Guide

Updated: 19 Nov 2024

1014

Metallurgical is the science and art of working with metals. It plays a crucial role in shaping the materials that are used in everyday life, from the cars we drive to the buildings we live in. The process involves extracting metals from ores, refining them, and then using them in different ways to create useful products. Metallurgy is not only about the metals themselves but also about how they can be shaped and treated to make them stronger, more durable, and suitable for various purposes.

Metals like iron, copper, and aluminum are used in countless industries, from construction to electronics. Understanding metallurgy helps us use these metals efficiently and responsibly. In this article, we will explore the different stages of the metallurgical process, how metals are extracted, and the important role metallurgy plays in shaping our modern world.

What Does “Metallurgical” Mean?

Metallurgical is a word that comes from “Metallurgical,” which is all about studying and working with metals. Imagine the shiny metals we see around us, like the steel in bridges, the gold in jewelry, or the aluminum in soda cans. Metallurgical is the science that helps us understand these metals, how they behave, and how we can use them to make useful things.

When something is called “metallurgical,” it means it is related to this science of metals. For example, metallurgical processes involve melting, shaping, or mixing metals to create strong tools, machines, and even tiny parts for computers.

You May Also Visit It!

Spray Arc Welding – Step by Step Guide – Need Metals

Pre Coat Metal | Define Complete Guide- Need Metals

Mcelroy Metals – Types, Uses And Properties – Need Metals

Will Magnets Stick to Stainless Steel Refrigerator – Complete Guide

The Basics of Metal Extraction

Metal extraction is the process of getting metals from their natural sources, usually ores. Ores are rock-like materials that contain enough metal to make it worth extracting. The process of extracting metals is important because it provides us with the raw materials needed to make everyday products like electronics, cars, buildings, and more.

Types of Metals

Metals come in many different types, such as iron, copper, gold, aluminum, and silver. Each of these metals has different properties, which is why they are used in different ways. For example, iron is strong and is used to make steel, while gold is soft and shiny and is used in jewelry and electronics.

Methods of Metal Extraction

There are several ways to extract metals from ores. The main methods are:

- Mining

- The first step in metal extraction is mining. This is when large amounts of earth are dug up to find ores that contain metals. Mines can be underground or on the surface of the earth.

- Smelting

- After ores are mined, they are heated to very high temperatures in a furnace. This process is called smelting. During smelting, the metal is separated from other materials in the ore. For example, in iron extraction, iron ore is heated with coke (a type of coal) and limestone. The heat causes the iron ore to melt, and the metal is collected at the bottom of the furnace.

- Refining

- Once the metal is extracted, it may still have impurities, such as other metals or minerals. To remove these impurities, the metal goes through a refining process. This can involve additional heating, chemical reactions, or even using electricity to make the metal pure and ready for use.

Step-by-Step Process of Extracting Metals

- Finding the Ore

- The first step in metal extraction is locating the right ore. Geologists search for ores using tools and techniques to find areas where metals are likely to be found.

- Mining the Ore

- Once the ore is found, it is extracted from the ground through mining. This can be done by digging tunnels underground or by using large machines to remove the top layer of earth and expose the ore.

- Crushing and Grinding

- After the ore is mined, it is crushed into smaller pieces. This makes it easier to extract the metal from the ore.

- Heating and Smelting

- The crushed ore is heated in a furnace to separate the metal from other elements in the ore. For example, iron is separated from its ore by heating it with coke. The high temperature melts the ore, allowing the metal to be collected at the bottom of the furnace.

- Refining the Metal

- The final step is refining. The metal is purified by removing any leftover impurities. This makes the metal strong and ready to be shaped into useful products.

Types of Metallurgy

Metallurgy is the science and technology of extracting, refining, and shaping metals, and it includes various types such as physical, chemical, extractive, powder, and alloy metallurgy, each focusing on different processes and techniques. Here are some types of metallurgy:-

- Physical Metallurgy

- Chemical Metallurgy

- Metallurgical Engineering

- Extractive Metallurgy

- Powder Metallurgy

- Alloy Metallurgy

Physical Metallurgy

Physical metallurgy focuses on the study of the physical properties of metals and their behavior when subjected to different conditions like heat or pressure. It looks at how metals are formed, shaped, and how they react to changes in temperature.

- Key Concepts in Physical Metallurgy

- Metal Strength

- Heat Treatment (like annealing, quenching)

- Metal Alloys and Their Properties

Chemical Metallurgy

Chemical metallurgy deals with the chemical processes used to extract metals from ores and purify them. It uses chemical reactions to separate valuable metals from other elements in ores.

- Key Processes in Chemical Metallurgy

- Smelting (using heat to extract metal)

- Leaching (using chemicals to dissolve metals)

- Electrolysis (using electricity to extract metal)

Metallurgical Engineering

Metallurgical engineering focuses on designing and improving the processes used in metallurgy. Engineers work on creating new ways to extract and refine metals, improving existing techniques, and ensuring metals are used efficiently in different industries.

- Roles of Metallurgical Engineers

- Designing furnaces and reactors

- Creating new metal alloys

- Solving problems related to metal production

Extractive Metallurgy

Extractive metallurgy is the process of extracting metals from ores using physical and chemical methods. This is a step-by-step process where ores are mined, crushed, separated, and then processed to obtain valuable metals.

- Common Methods in Extractive Metallurgy

- Crushing and grinding ores

- Smelting and refining

- Leaching and electrolysis

Powder Metallurgy

Powder metallurgy is a process where metals are turned into fine powders and then molded or shaped into solid forms. This technique is often used to make parts with precise shapes, such as gears or tools.

- Key Processes in Powder Metallurgy

- Powder Production (turning metals into powder)

- Powder Compaction (pressing the powder into shapes)

- Sintering (heating the powder to bind it into solid form)

Alloy Metallurgy

Alloy metallurgy focuses on the study and creation of alloys, which are mixtures of two or more metals. Alloys have unique properties that make them useful for specific applications, like stronger materials for construction or lighter metals for vehicles.

- Types of Alloys

- Steel (Iron and Carbon)

- Bronze (Copper and Tin)

- Brass (Copper and Zinc)

Types of Metallurgical Industries

Metallurgical industries are divided into different types based on the processes and products they produce. These industries play a crucial role in shaping the world’s materials, which are used in many different fields. Here are the main types of metallurgical industries:

- Primary Metallurgical Industry

- Secondary Metallurgical Industry

- Specialized Metallurgical Industries

- Primary Metallurgical Industry

- This industry focuses on extracting metals from ores. The main processes used include mining, smelting, and refining. Metals like iron, copper, and aluminum are produced here. The primary metallurgical industry lays the foundation for producing raw metals.

- Secondary Metallurgical Industry

- In this industry, raw metals produced in the primary industry are further processed. It includes shaping, casting, and alloying metals to create different products like bars, sheets, and pipes. The secondary industry is responsible for refining metals into more useful forms for construction, manufacturing, and other applications.

- Specialized Metallurgical Industries

- These industries focus on producing specific types of metals or alloys. Examples include industries that produce precious metals like gold and silver or specialized alloys used in high-tech equipment. The specialized metallurgical industry makes metals that are used in advanced technologies like aerospace and electronics.

Each type of metallurgical industry is important in its own way, helping to produce the metals we use in our daily lives and in high-tech industries.

Historical Background of Metallurgical

Long ago, people found shiny rocks in the ground. They learned that these rocks had metal inside. The first metal used was copper. People hit it with stones to make tools. Later, they found tin and mixed it with copper to make bronze. This new metal was stronger, and it helped them make better weapons and tools. This time was called the Bronze Age.

After many years, people learned how to use iron. Iron was even stronger than bronze. It helped build better tools, farming items, and even big buildings. This time became known as the Iron Age.

Over time, people made better ways to melt and shape metal. They built hot ovens called furnaces. These helped them get pure metal from rocks. Later, they used coal to make fire hotter and melt more metal.

As years passed, people started learning more about how metal works. They studied how to make metal harder, softer, or shiny. They also made new types of metal called alloys, like steel.

That is how metallurgy slowly grew from simple tools to the strong and smart metal work we use today.

Uses of Metallurgical

Metallurgical is not just about working with metals; its used in so many things that we use every day. Here are some of the cool ways metallurgical helps make the world a better place:

- Construction

- Transportation

- Electronics

- Tools and Machinery

- Jewelry

- Energy Production

- Medical Applications

- Aerospace

- Building Strong Structures

- Construction

- Metallurgy is used to create strong materials for building structures like bridges, buildings, and roads. For example, steel is used in the construction of skyscrapers because of its strength and durability.

- Transportation

- Metals are essential for making vehicles like cars, trains, and airplanes. Aluminum, for instance, is used in airplane bodies to keep them light and strong, making air travel safer and more efficient.

- Electronics

- Metals like copper and gold are used in making electrical circuits for gadgets like phones and computers. Copper is a great conductor of electricity, making it perfect for wiring in electronics.

- Tools and Machinery

- Metallurgy helps create strong tools and machinery used in factories, farms, and construction. Steel is commonly used for making tools like hammers and drills because of its toughness and ability to last long.

- Jewelry

- Precious metals like gold, silver, and platinum are used in making jewelry. Gold is particularly popular for making rings, necklaces, and bracelets due to its beauty and value.

- Energy Production

- Metals like copper are vital in power plants and energy systems. Copper wires are used to carry electricity from power stations to homes and businesses.

- Medical Applications

- In the medical field, metals like titanium are used to make implants and surgical tools. Titanium is lightweight and strong, making it ideal for joint replacements and dental implants.

- Aerospace

- Metallurgy is crucial in aerospace for making materials that can handle extreme conditions. Titanium and aluminum are used in building spacecraft and airplanes, helping them withstand high temperatures and pressures.

- Building Strong Structures

- Metallurgy helps create materials that are strong and reliable, like steel, used in the construction of buildings and bridges that need to support heavy loads. Steel beams, for example, help ensure the stability of large structures.

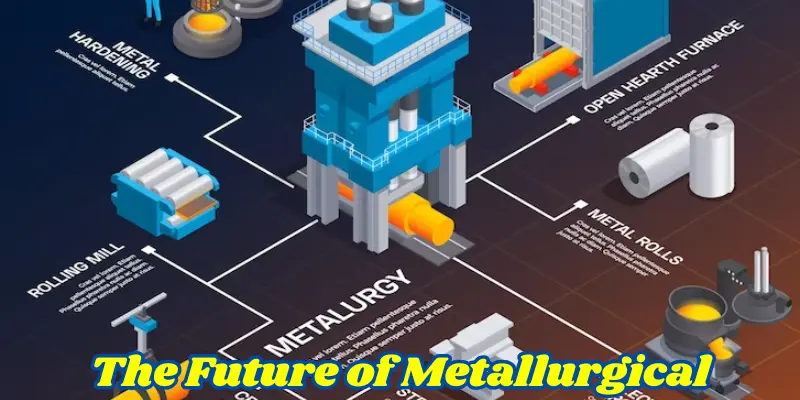

The Future of Metallurgical

Metallurgical is always changing and improving. As technology advances, so do the ways we work with metals. The future of metallurgical is exciting because there are many new discoveries and ideas that can make our world better. Here are some of the exciting things that might happen in the future of metallurgical:

- New and Better Materials

- Scientists are constantly working on creating new metals and alloys that are even stronger, lighter, and more resistant to things like rust and wear. For example, there research into metals that can help make vehicles lighter and more fuel efficient, or new materials that can be used in space travel.

- Recycling Metals

- In the future, recycling will become even more important. Metallurgical is already helping us recycle metals like aluminum and steel, but new techniques will make it easier to recycle more metals from old products. This is great for the environment because it reduces the need to dig up new metals from the Earth.

- Smarter Manufacturing

- New technology, like robots and 3D printing, is changing how we make metal products. In the future, 3D printers might be used to make everything from airplane parts to medical devices. This will allow engineers to make metals into any shape they need, while also saving material and energy.

- Metals for Clean Energy

- The future of metallurgical is also tied to helping the planet. Metallurgical is being used to create better materials for clean energy sources like solar panels and wind turbines. These materials will help produce more energy with less pollution, which is great for protecting the Earth.

- Space Exploration

- As we explore space, new metals and alloys will be needed to build spacecraft that can survive in extreme conditions. Metallurgists are working on materials that can handle the heat and pressure of space travel. This means that in the future, metallurgical might help us travel to the Moon, Mars, and beyond.

Metallurgical is already an important part of our world, and the future looks even more promising. With new materials, better recycling methods, and advances in technology, metallurgical will continue to make our world safer, cleaner, and more efficient.

You May Also Visit It!

Forging Process | Metal Becomes Tools and Parts – Easy Explanation

History of Nickel | From Ancient Coins to Modern Technology

Metal Does a Magnet Not Stick To | Uses and Types

Physical Properties Are Shared by Most Metals

Advantages and Disadvantages of Metallurgical

Metallurgical, the science and technology of working with metals, has a huge impact on our world. But like any technology, it has both advantages and disadvantages.

Advantages of Metallurgical

Metallurgy offers many benefits by turning raw metals into useful materials that improve our daily lives.

| Pros of Metallurgical |

|---|

|

Disadvantages of Metallurgical

Metallurgy is useful in many ways, but it also has some disadvantages that can affect people and the environment.

| Cons of metallurgical |

|---|

|

Common FAQs on Metallurgical

Here are some common FAQs about metallurgical written in an easy and user friendly language:

What is metallurgical?

Metallurgical is the study and use of metals to create useful products and materials.

What are the main branches of metallurgical?

There are three main branches of metallurgical:

- Extractive Metallurgical

- Physical Metallurgical

- Mechanical Metallurgical

What are some key techniques used in metallurgical?

There are six Key techniques in metallurgical:

- Smelting

- Casting

- Forging

- Rolling

- Alloying

- Heat Treatment

How does metallurgical contribute to clean energy?

Metallurgy supports clean energy by providing strong and efficient metals used in wind turbines, solar panels, electric vehicles, batteries, and power lines, helping produce and store energy without pollution.

Conclusion

Metallurgical is the fascinating science of working with metals, helping to shape the world we live in. From ancient times to modern technology, it has played a crucial role in building strong materials for tools, structures, and machines. Whether its through the development of alloys, advancements in recycling, or innovations in space exploration, metallurgical touches many parts of our daily lives.

While it has some environmental and energy related challenges, the future of metallurgical holds exciting possibilities, including the creation of more sustainable and efficient materials. Its clear that metallurgical will continue to drive progress and shape industries for years to come.

You May Also Visit It!

Magnetic Materials | What Materials Are Attracted By Magnets – Benefits

Yield Strength of Metals: Types, Uses and Clear and Simple Overview

Heat Treating Steel | Key Temperatures for Hardening, Types and Uses

1075 or 1095 Steel | Find the Best Steel for Your Knife

Aluminium Metal, Types, Uses, Properties and Rust Aluminium

Please Write Your Comments