Why Thermal Copper is Essential for Heat Management

Updated: 04 Nov 2024

502

Thermal copper is more than just a metal its a vital component in many industries, known for its exceptional ability to conduct heat efficiently. Whether you’re an engineer, a DIY enthusiast, or simply curious about materials, understanding thermal copper can open doors to innovative applications and solutions.

This remarkable material boasts a thermal conductivity of approximately 401 W/m·K, making it one of the best conductors available. Its applications range from electrical wiring and heat exchangers to cookware and automotive components, showcasing its versatility and importance in modern technology.

As we delve deeper into the world of thermal copper, we’ll explore its unique properties, benefits, and the cutting-edge innovations that make it indispensable for effective heat management. Join us on this journey to discover how thermal copper can enhance efficiency and performance in various fields.

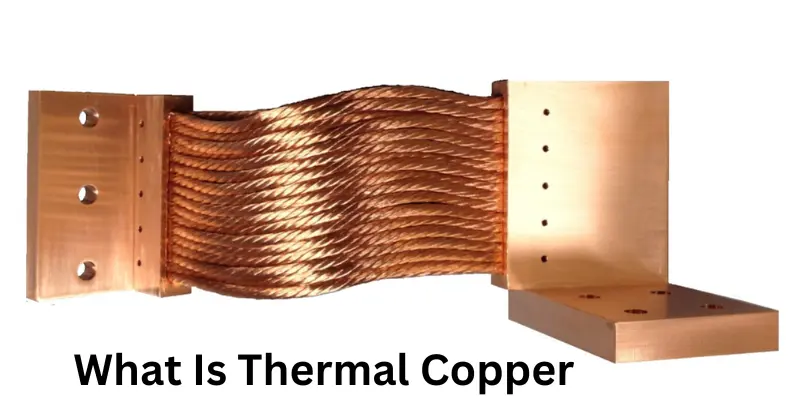

What is Thermal Copper?

Thermal copper is a special kind of copper that is really good at conducting heat. Think of it like a superhero for heat! When heat needs to move from one place to another, thermal copper helps it travel quickly and efficiently. This property makes it super useful in many everyday items.

For example, you can find thermal copper in things like cooktops, where it helps to heat up your food evenly, or in electronic devices, where it keeps them from getting too hot. It’s also used in cars to make sure the engines work well by managing the heat produced during driving.

In addition to being a great heat conductor, thermal copper is durable and can last a long time, making it a popular choice in industries like electronics and construction. So, next time you see a cooking pot or an electronic gadget, remember that thermal copper might be helping it work better by keeping things at the right temperature.

You May Also Visit It!

Spray Arc Welding – Step by Step Guide – Need Metals

Pre Coat Metal | Define Complete Guide- Need Metals

Mcelroy Metals – Types, Uses And Properties – Need Metals

Will Magnets Stick to Stainless Steel Refrigerator – Complete Guide

Applications of Thermal Copper

Thermal copper is utilized in a variety of exciting applications due to its exceptional heat conductivity. Here are some of the key areas where you can find it:

- Cooking Pots and Pans: Many chefs prefer cookware made from thermal copper for its ability to heat quickly and evenly. This results in perfectly cooked meals without hot spots that can scorch some areas while leaving others undercooked.

- Electronics: Thermal copper plays a vital role in devices such as computers and smartphones. It effectively dissipates heat from sensitive components, helping these gadgets operate more efficiently and prolonging their lifespan by preventing overheating.

- Automobiles: In the automotive industry, thermal copper is employed in components that manage the heat generated by engines. Proper heat management is crucial to prevent engine failure, and thermal copper ensures that engines maintain optimal temperatures during operation.

- Heat Exchangers: Thermal copper is commonly used in heat exchangers, devices designed to transfer heat between two or more fluids. Its efficient heat transfer capabilities are essential for various heating and cooling systems.

- Renewable Energy: Thermal copper also plays an important role in solar panels, aiding in the collection and transfer of solar heat, which enhances the efficiency of energy generation.

Thermal copper is an outstanding material that enhances cooking, cools our electronics, facilitates smooth automobile operation, and harnesses solar energy. Its unique properties make it an indispensable element in our everyday lives.

Comparing Thermal Copper to Other Materials

Thermal copper is frequently compared to other heat-conducting materials like aluminum and graphite. Let’s explore how they measure up against each other!

1. Thermal Copper vs. Aluminum

- Conductivity: Thermal copper is a superior heat conductor compared to aluminum, allowing it to transfer heat more quickly and evenly. This quality makes it a popular choice in cooking and electronics.

- Weight: Aluminum is lighter than copper, which can be beneficial in applications such as aviation or portable devices. However, thermal copper’s higher density provides enhanced stability and durability.

- Cost: Generally, copper is more expensive than aluminum, making aluminum a more budget-friendly option for certain projects.

2. Thermal Copper vs. Graphite

- Conductivity: Although graphite also has good heat-conducting properties, thermal copper typically outperforms it in many applications. As a result, copper is often preferred for high-performance uses, such as in electronic devices.

- Flexibility: Graphite is softer and easier to shape than copper, making it suitable for specific applications like lubricants and batteries. However, it lacks the durability of thermal copper.

- Cost and Availability: Copper is generally more accessible and easier to work with than graphite, making it a preferred material for many manufacturers.

While thermal copper excels as a heat conductor, materials like aluminum and graphite offer distinct advantages. The choice of material often depends on the specific application be it cooking, electronics, or other uses.

Manufacturing Processes for Thermal Copper

The production of thermal copper is a fascinating process that transforms raw copper into the valuable material we recognize today. Here’s an overview of the key steps involved:

- Mining and Smelting: The journey begins with extracting copper from the earth. Copper ore is typically mined from large open pits. After extraction, the ore is crushed and subjected to a process known as smelting, where it is heated to separate the copper from other materials in the ore. This results in a viscous, reddish-brown liquid called molten copper.

- Casting: Once the copper has reached its molten state, it can be poured into molds to form various shapes in a process called casting. For instance, to create a flat sheet of copper, the molten copper is poured into a flat mold. Upon cooling, it solidifies and is ready for numerous applications.

- Rolling: After casting, the solid copper can be rolled into thin sheets or wires. This is accomplished using large machines that apply pressure to flatten the copper to the desired thickness. Rolling facilitates easier handling of copper in subsequent processes, particularly for producing items like pipes, sheets, and electrical wires.

- Extrusion: Another method for shaping copper is extrusion. In this technique, the copper is heated until it becomes pliable and is then forced through a specialized mold, producing long forms such as rods or tubes. Extrusion is particularly effective for creating strong and elongated products.

- Finishing Processes: The final step involves various finishing processes, which may include cleaning, polishing, and applying protective coatings to prevent damage or tarnishing. These finishing touches ensure that the thermal copper products are durable and perform optimally in their intended applications.

The manufacturing of thermal copper encompasses several intriguing stages, from mining and smelting to casting, rolling, and extruding. Each step is crucial in producing high-quality thermal copper suitable for a wide range of products.

Innovations in Thermal Copper Technology

The field of thermal copper is continually evolving and improving! With the introduction of new ideas and technologies, thermal copper is enhancing its heat conduction capabilities and finding exciting new applications. Let’s delve into some of the most remarkable innovations in thermal copper technology!

- Advanced Alloys: Researchers are developing specialized blends of copper with other metals, known as alloys. These innovative alloys can significantly improve thermal conductivity, making them ideal for high-performance applications. For instance, incorporating materials like silver or aluminum into copper can result in highly efficient heat conductors that are both lightweight and durable.

- 3D Printing: Did you know that thermal copper can be 3D printed? Utilizing advanced 3D printing technology, manufacturers can produce intricate shapes using thermal copper powder. This capability allows for customized designs in electronics and various industries, akin to having a high-tech printer that creates specialized thermal copper components right before your eyes.

- Nanotechnology: Scientists are investigating the application of tiny particles, known as nanoparticles, to enhance thermal copper. These nanoparticles can improve copper’s heat conduction efficiency, enabling the creation of smaller, lighter devices that maintain excellent performance. By leveraging nanotechnology, engineers are pushing the boundaries of thermal copper applications.

- Smart Thermal Management Systems: Innovations in thermal copper are also leading to the development of intelligent systems that automatically regulate heat. These systems utilize sensors and advanced technology to optimize heat distribution in devices, ensuring they remain cool while conserving energy. This is particularly crucial for electronics like computers and smartphones, where overheating can lead to significant issues.

- Sustainable Practices: Finally, there is a growing emphasis on making thermal copper production more environmentally friendly. Companies are exploring ways to recycle old copper and minimize waste, making the entire process more sustainable. This approach allows us to enjoy the benefits of thermal copper while also protecting our planet.

Innovations in thermal copper technology are making it stronger, smarter, and more efficient than ever before. From advanced alloys and 3D printing to nanotechnology and sustainable practices, the future of thermal copper is looking very promising.

You May Also Visit It!

Forging Process | Metal Becomes Tools and Parts – Easy Explanation

History of Nickel | From Ancient Coins to Modern Technology

Metal Does a Magnet Not Stick To | Uses and Types

Physical Properties Are Shared by Most Metals

Advantages and Disadvantages of Thermal Copper

When it comes to the use of thermal copper, there are several benefits and drawbacks to keep in mind. Here a friendly overview of both sides.

Advantages of Thermal Copper

| Advantages |

|---|

|

Disadvantages of Thermal Copper

| Disadvantages |

|---|

|

Thermal copper is a remarkable material with many advantages, including outstanding heat conductivity and durability.

Common FAQs About Thermal Copper

Here are some frequently asked questions about thermal copper, answered in a simple and friendly way.

1. What is thermal copper?

Thermal copper is a type of copper known for its excellent heat-conducting properties. It’s commonly used in various products, including cookware, electronics, and heat exchangers, due to its efficient heat transfer capabilities.

2. Why is thermal conductivity important?

Thermal conductivity measures how well a material can transfer heat. Materials with high thermal conductivity, like thermal copper, help regulate temperature quickly, which is especially important in cooking and electronics, where effective heat management is essential.

3. How is thermal copper made?

The production of thermal copper involves several steps. First, copper ore is mined and smelted to eliminate impurities. Next, the copper is cast into various shapes, rolled into sheets or wires, or extruded into tubes. Finally, it undergoes finishing processes to ensure it is ready for use.

4. What are the advantages of using thermal copper?

Thermal copper offers numerous advantages, including excellent heat conductivity, durability, versatility in shaping, and recyclability. Its attractive appearance also makes it a popular choice for a wide range of applications.

5. Are there any disadvantages to thermal copper?

Yes, there are a few drawbacks. Thermal copper can be more expensive than alternatives like aluminum, and it is heavier, which may not be suitable for all applications. Additionally, tarnishing or corrosion can reduce its heat conduction efficiency.

6. Where is thermal copper commonly used?

You shall find thermal copper in cookware, electrical wiring, heat exchangers, and many electronic devices. Its superior heat-conducting ability makes it a preferred material in these areas.

7. Can thermal copper be recycled?

Thermal copper is highly recyclable. When copper products reach the end of their life cycle, they can be melted down and reused to create new items, helping to reduce waste and benefiting the environment.

8. How does thermal copper compare to aluminum?

Thermal copper conducts heat more efficiently than aluminum, making it a superior choice in many cases. However, aluminum is lighter and less expensive, which can make it more suitable for certain applications, such as in airplanes or portable electronics.

9. What innovations are happening in thermal copper technology?

Recent innovations include the development of advanced alloys, the use of 3D printing for custom shapes, exploration of nanotechnology for enhanced conductivity, and the creation of smarter thermal management systems.

Bonus Points

- Heat Sink Applications: Thermal copper is frequently utilized in heat sinks for electronics due to its exceptional ability to dissipate heat. This prevents devices from overheating, ensuring they operate smoothly and have a longer lifespan.

- Electrical Conductivity: In addition to its excellent heat conduction, thermal copper is also highly effective at conducting electricity. This property makes it a preferred material for electrical wiring and components.

- Culinary Uses: In the culinary world, copper cookware is favored by chefs for its ability to distribute heat quickly and evenly, enhancing cooking efficiency and precision. Many premium cooking utensils incorporate a layer of thermal copper for this reason.

- Sustainable Production: Advances in copper recycling have led to more sustainable production practices. By reusing copper, we can lessen environmental impact and conserve natural resources.

- Temperature Sensors: Thermal copper is also used in temperature sensors and thermocouples, where its reliable thermal properties ensure accurate temperature readings. This is crucial for various industrial applications.

These bonus points illustrate the versatility and significance of thermal copper in our everyday lives and across different industries.

Conclusion

Thermal copper is a fantastic material known for its excellent heat conductivity, durability, and versatility. It plays a crucial role in many everyday items, from cooking pots to electronics.

While it has some disadvantages, like being heavier and more expensive than alternatives, its benefits often outweigh these downsides. With ongoing innovations in thermal copper technology, we can expect even more exciting uses and improvements in the future.

You May Also Visit It!

Magnetic Materials | What Materials Are Attracted By Magnets – Benefits

Yield Strength of Metals: Types, Uses and Clear and Simple Overview

Heat Treating Steel | Key Temperatures for Hardening, Types and Uses

1075 or 1095 Steel | Find the Best Steel for Your Knife

Aluminium Metal, Types, Uses, Properties and Rust Aluminium

Please Write Your Comments