Phase Diagram for Steel | Unlocking the Secrets of Strength

Updated: 23 Nov 2024

660

Introduction

Have you ever wondered what gives steel its incredible versatility, strength, and durability? The secret lies in understanding the Iron Carbon Phase Diagram, a foundational tool in metallurgy. This diagram illustrates how different combinations of iron, carbon, and heat transform the properties of steel, making it suitable for everything from skyscrapers to surgical instruments.

The phase diagram is not just a chart; its a roadmap that guides engineers and scientists in tailoring steels microstructure for specific applications. Whether its creating ultra strong martensite for cutting tools or ductile pearlite for construction, the diagram holds the answers.

In this article, well break down the Phase Diagram for Steel into simple, easy to understand terms, exploring its key phases, critical points, and practical applications. Whether you are a student, engineer, or enthusiast, you will walk away with a clearer understanding of why this diagram is crucial to modern industry.

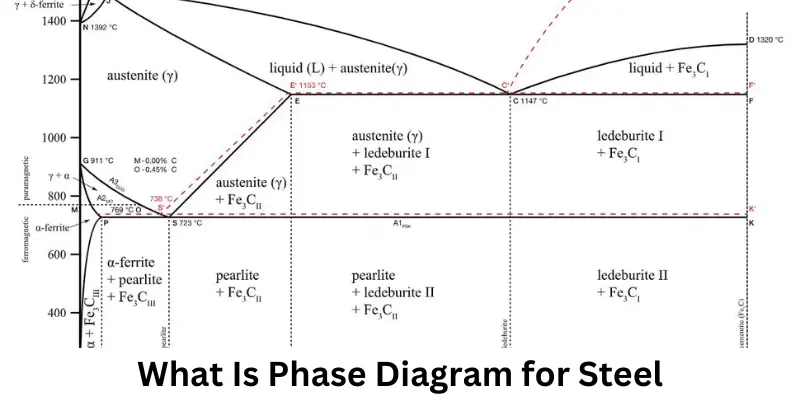

What Is Phase Diagram for Steel?

Imagine you are baking cookies. The ingredients and the temperature in the oven change how the cookies turn out soft, crispy, or chewy. The Phase Diagram for Steel works the same way, but for steel. Its like a recipe chart that shows what happens to a mixture of iron and carbon when you change the temperature or the amount of carbon.

Steel is made mostly of iron, but adding a little carbon changes its strength, hardness, and flexibility. The phase diagram is a special chart that helps scientists and engineers figure out what kind of steel they are making. It shows when steel is soft and bendy, super hard, or somewhere in between.

For example:

- If you heat steel to a high temperature and cool it very fast, it becomes super strong but might break easily (like martensite).

- If you cool it slowly, it might be softer but more flexible (like ferrite and pearlite).

This diagram is super important because it helps us make steel that perfect for building bridges, making cars, or even creating tiny tools. Its like a secret map that helps people make steel just right for any job.

You May Also Visit It

Copper Zinc Alloys – Step by Step Guide

Cast Iron Melting Temp | Discover Its Industrial Secrets

Is Aluminium Magnetic Material | Types, Uses and Properties

Physical Properties Are Shared by Most Metals

Why Is the Phase Diagram for Steel Important?

The Phase Diagram for Steel is more than just a chart; its a cornerstone in the world of materials science and engineering. It plays a crucial role in understanding, designing, and manufacturing steel with the desired properties for countless applications.

1. Helps in Understanding Steel Behavior

The diagram explains how steel behaves when exposed to different temperatures and carbon contents, making it easier to predict its properties.

- It shows how phases like ferrite, austenite, pearlite, and martensite form.

- Helps engineers understand the relationship between microstructure and mechanical properties.

2. Guides Heat Treatment Processes

Heat treatment changes steel properties, and the phase diagram acts as a guide for this process.

- Optimizes quenching, annealing, and tempering techniques.

- Ensures steel achieves the right balance of hardness, ductility, and toughness.

3. Tailors Steel for Specific Applications

Different industries require steel with varying characteristics, and the phase diagram makes customization possible.

- Hard and wear resistant martensitic steel for cutting tools.

- Flexible ferritic steel for pipes and automotive parts.

4. Provides Insights into Critical Temperatures

It highlights essential temperature points, such as:

- Eutectoid Temperature (723°C): Key for transforming austenite into pearlite.

- Melting Points: Useful in casting and welding processes.

5. Supports Alloy Development

Adding elements like manganese or chromium changes steels behavior, and the phase diagram helps predict these effects.

- Aids in creating advanced steels for construction, aerospace, and medical industries.

- Explains how alloying impacts phase stability.

6. Enhances Industrial Efficiency

By understanding the phase diagram, manufacturers can:

- Minimize material waste.

- Reduce trial and error in steel production.

- Save time and costs in developing new products.

7. Ensures Material Reliability

For safety critical applications like bridges, airplanes, or medical implants, the phase diagram ensures:

- The steel meets required performance standards.

- Long term durability under various conditions.

The Phase Diagram for Steel is a vital tool that bridges the gap between theory and practical application. It empowers engineers, scientists, and manufacturers to design and use steel effectively, ensuring high quality results in everything from skyscrapers to surgical instruments. Understanding this diagram is key to unlocking steel full potential.

Key Phases in the Diagram

The Phase Diagram for Steel has several important “phases,” which are like different states of steel depending on its temperature and carbon content. These phases tell us how hard, soft, or flexible the steel will be.

1. Ferrite (α-Iron)

- What it is: Ferrite is a soft and bendy form of steel.

- When it happens: It forms at lower temperatures and has very little carbon in it.

- Why its important: Its easy to shape and is often used for parts that do not need to be super strong.

2. Austenite (γ-Iron)

- What it is: Austenite is a form of steel that exists at high temperatures.

- When it happens: It forms when steel is heated to a specific temperature range.

- Why its important: Its crucial for making other phases like martensite and pearlite when cooled.

3. Cementite

- What it is: Cementite is a hard and brittle phase made mostly of carbon.

- When it happens: It appears when steel has a lot of carbon.

- Why its important: It makes steel harder but also less flexible.

4. Pearlite

- What it is: Pearlite is a mix of ferrite and cementite. It looks like layers under a microscope.

- When it happens: It forms when steel cools slowly from the austenite phase.

- Why its important: It gives steel a balance between strength and flexibility.

5. Martensite

- What it is: Martensite is super hard but can break easily if its not treated properly.

- When it happens: It forms when steel is cooled very quickly (quenched) from a high temperature.

- Why its important: Its used for tools and parts that need to be extremely strong.

Each phase gives steel a unique property, like softness, strength, or hardness. By controlling the temperature and carbon content, we can choose which phase forms and make steel perfect for the job whether its for building bridges, making cars, or crafting tools.

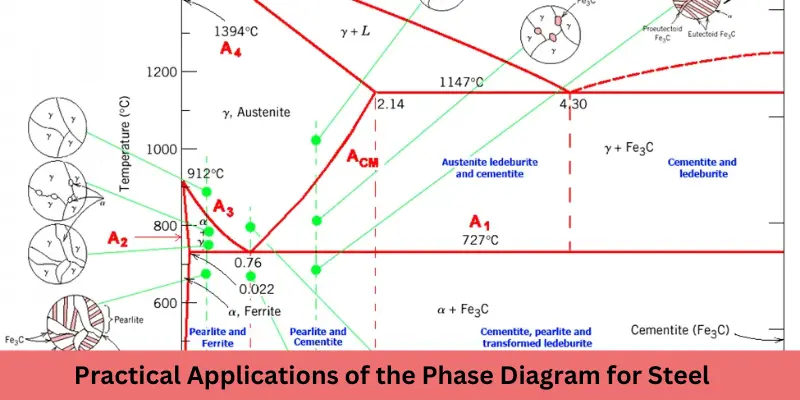

Practical Applications of the Phase Diagram for Steel

The Phase Diagram for Steel is not just something scientists and engineers use in labs its a tool that helps make steel the perfect material for all sorts of important things in our everyday lives. Let look at some practical uses of steel that depend on understanding its phases.

1. Building Strong Bridges and Skyscrapers

Steel is the backbone of most large buildings and bridges. By using the phase diagram, engineers can choose the right type of steel to make sure these structures are both strong and safe. For example:

- Martensite is used when we need super strong, tough steel that can support a lot of weight without breaking.

- Pearlite helps in creating steel that is strong but also a bit flexible, so it would not crack easily when under stress.

2. Making Cars and Trucks

Steel is a key material in cars and trucks. Different parts of the vehicle require different types of steel. The phase diagram helps engineers decide:

- Cementite can be used for parts that need to be hard and wear resistant, like engine components.

- Ferrite might be used for parts that need to bend and absorb impact, like bumpers or car frames.

3. Tools and Machinery

We need tools that can cut, shape, or weld other materials, and steel is perfect for that. Steel phases play a big role here:

- Martensite gives us super hard steel, perfect for tools like knives, scissors, and drills.

- Pearlite and ferrite are used for softer tools like hammers, where a little flexibility is needed.

4. Medical Implants

Steel is not just for buildings and vehicles its also used in medicine. Some medical tools and implants, like surgical instruments or even artificial joints, are made of steel. The phase diagram helps make sure these tools are both strong and safe for use in the body. For example:

- Cementite makes steel hard enough for tools like scalpels and forceps.

- Pearlite is used to ensure the steel is not too brittle.

5. Everyday Household Items

From kitchen appliances to bicycles, steel is everywhere in our homes. Understanding the phase diagram helps manufacturers make steel that perfect for each job.

- Ferrite is used in items like kitchen knives that need to be sharp and flexible.

- Martensite can be used for bike frames that need to be lightweight yet strong.

The Phase Diagram for Steel, we can make steel that is just right for the job. Whether its building a bridge, making a car, or creating a tool, the phases of steel help engineers choose the perfect mix to make everything work safely and efficiently.

You May Also Visit It

What is Ferrous vs Non Ferrous Metals – Complete Guide

What is Titanium Steel – Types, Uses, Properties and Modern Metal

Plasma Cutter How Does It Work – Complete Guide

Is Copper a Metalloid | Understanding the Classification of Elements

Advantages and Disadvantages Phase Diagram for Steel

Here is some advantages and disadvantages of phase diagram for steel:

Advantages of Phase Diagram for Steel

The Phase Diagram for Steel is an essential tool in metallurgy and engineering because it offers several benefits that make steel production and application more efficient and reliable. Here are some of the advantages:

| Advantages |

|---|

|

1. Precise Control Over Steel Properties The phase diagram allows engineers to control the properties of steel by adjusting the temperature and carbon content. This leads to:

2. Better Heat Treatment Processes With the phase diagram, engineers can optimize heat treatment processes such as quenching and tempering. This ensures steel achieves the perfect balance between hardness and toughness, preventing it from becoming too brittle or soft.

3. Improves Material Efficiency The diagram helps manufacturers use the exact steel needed for each project. This prevents unnecessary material use and saves costs.

4. Predicts Phase Changes Accurately The diagram accurately predicts phase transformations in steel as it heats or cools, providing a reliable way to understand how steel will behave under different conditions.

5. Enables Alloy Development

|

Disadvantages Phase Diagram for Steel

While the phase diagram for steel is invaluable, there are some drawbacks and limitations that need to be considered:

| Disadvantages |

|---|

|

1. Complexity for Beginners The diagram can be difficult to understand for those without a background in materials science or metallurgy.

2. Limited to Basic Steel Types The phase diagram is primarily designed for carbon steels, and while it can be helpful for certain alloy steels, it does not fully address the complexities of modern high alloy steels.

3. Assumes Ideal Conditions The phase diagram assumes ideal conditions in the laboratory or controlled settings, which may not always match real world environments.

4. Does Not Account for External Factors The diagram does not take into account the effects of stresses or strains on the steels performance during manufacturing processes or during its lifespan in use.

|

The Phase Diagram for Steel is an essential tool for producing steel with specific qualities for various uses, from bridges to surgical tools. While it offers many advantages, such as precise control over steel properties and better material efficiency, it also comes with some challenges, including its complexity and limitations when dealing with modern alloys and real world conditions. Understanding both the strengths and weaknesses of the phase diagram helps engineers and scientists make informed decisions in steel production and application.

Common FAQs about the Phase Diagram for Steel

Here are some frequently asked questions (FAQs) about the Phase Diagram for Steel, explained in simple terms:

What is a Phase Diagram for Steel?

A phase diagram for steel is like a map that shows how steel behaves at different temperatures and carbon contents. It helps engineers understand the different “phases” (or forms) steel can take, such as being hard and brittle or soft and flexible. This helps in choosing the right type of steel for various uses.

Why is the Phase Diagram Important?

The phase diagram is important because it:

- Helps engineers control the strength, flexibility, and hardness of steel.

- Allows the creation of steel with specific properties, like super strong tools or flexible car parts.

- Helps in choosing the right heat treatment processes to make steel stronger or softer, depending on what its needed for.

What Are the Key Phases in the Phase Diagram for Steel?

Steel has several important phases, each with its own properties:

- Ferrite (soft and bendy)

- Austenite (used for shaping steel)

- Cementite (hard but brittle)

- Pearlite (balanced strength and flexibility)

- Martensite (super hard)

Each phase forms at different temperatures and carbon contents, which is why the phase diagram is so helpful in making the right steel for the job.

How Does the Phase Diagram Help in Making Steel?

By using the phase diagram, manufacturers can:

- Control the cooling rates of steel to create different phases.

- Choose the right steel for specific jobs, like building bridges, making cars, or crafting tools.

- Predict how steel will behave under certain temperatures, avoiding mistakes during production.

Can the Phase Diagram Be Used for All Types of Steel?

The phase diagram mainly applies to carbon steels, but it is not as useful for complex alloy steels, which have many other elements mixed with iron and carbon. Engineers sometimes need additional diagrams for specific steel alloys used in advanced technology.

How Does Temperature Affect Steel According to the Phase Diagram?

The temperature has a huge impact on the phase of steel. For example:

- At lower temperatures, steel may be ferrite, which is soft and flexible.

- At higher temperatures, steel becomes austenite, which can be shaped and treated.

- Cooling steel at different rates (like quenching it rapidly) can change it into very hard forms like martensite.

Is the Phase Diagram Only Used in Manufacturing?

No, the phase diagram is used in many areas, including:

- Research: Scientists study it to understand the properties of steel.

- Designing Steel Parts: Engineers use it to create steel for specific needs like medical tools or machinery.

- Quality Control: It helps check if steel has been made correctly, with the right phases and properties.

What Are Some Real World Uses of the Phase Diagram for Steel?

The phase diagram is used in many industries, including:

- Construction: To make strong steel for buildings and bridges.

- Automotive: To create steel for car frames that need to be tough yet flexible.

- Medical: To make tools like scalpels or implants that need to be both strong and safe.

Can Steel Be Changed After Its Made Using the Phase Diagram?

Yes. Steel can be heated and cooled in different ways to change its phase. For example, it can be heated and cooled quickly (quenched) to make it very hard, or slowly cooled to make it softer and easier to shape. This is how steel can be adjusted for specific uses.

How Do Engineers Read the Phase Diagram?

Engineers read the phase diagram by looking at temperature and carbon content on the axes of the diagram. By finding where these factors meet, they can see what phase the steel will be in at that particular condition. This helps them predict how the steel will behave during manufacturing and in use.

These answers cover the basics of the phase diagram for steel and its uses. Understanding this diagram is essential for anyone working with steel in industries like construction, automotive, and manufacturing.

Bonus Points on the Phase Diagram for Steel

Here are a few bonus points to enhance your understanding of the phase diagram for steel:

1. Understanding Alloying Elements

- The phase diagram for steel primarily focuses on carbon content, but it also helps in understanding how other elements like manganese, chromium, and nickel influence the steel properties. These elements can shift phase boundaries, allowing the creation of stronger or more corrosion resistant steels, like stainless steel.

2. Influence of Cooling Rate

- The rate at which steel cools down from a high temperature plays a critical role in determining the final structure. Faster cooling (like quenching in water) can create hard phases like martensite, while slower cooling leads to more flexible phases like pearlite.

3. Application in Welding

- Phase diagrams are also used in welding to predict how the steel will behave when heated in the welding process. Understanding how different phases will form during welding helps prevent cracking and ensures the welded material is as strong as the original steel.

4. Steel Grades and Standards

- Different phases identified in the diagram correspond to specific steel grades. For example, steel with high carbon content tends to form cementite, making it harder but more brittle. Low carbon steels, on the other hand, may be softer and more suitable for tasks like forming or shaping.

5. Predicting Steel Behavior

- The phase diagram allows engineers to predict how steel will respond to different temperatures, which is key for heat treatment processes like hardening or tempering. These processes adjust steels hardness and toughness to meet specific needs.

These bonus points highlight some of the advanced uses and insights of the phase diagram for steel, helping industries create better materials and make informed decisions during production. Understanding the diagram nuances goes a long way in producing steel that meets the high demands of modern engineering.

Conclusion

The phase diagram for steel is a valuable tool that helps engineers and manufacturers understand how steel behaves at different temperatures and carbon levels. By studying this diagram, they can control the properties of steel, such as its strength, flexibility, and hardness, making it suitable for a variety of uses.

From construction to medical tools, the phase diagram plays a crucial role in ensuring that steel performs exactly as needed for different applications. By understanding the key phases and how temperature affects steel, industries can create better, more reliable materials for everyday use.

You May Also Visit It

Cast Iron Melting Temp | Discover Its Industrial Secrets

Metal Stamping Aluminum | Easy Steps to Understand Metal Stamping

Diagram of V8 Engine Explore the Power Behind Every Part

Welding Position | Types, Properties and Uses – Pros and Cons

What is Cold Roll Steel: Types, Grades and Uses | Pros and Cons

Please Write Your Comments