What is Tensile Strength | Materials, Secret Superpower

Updated: 01 Dec 2024

396

Have you ever tried stretching a rubber band and wondered why it does not break right away? Or why some ropes can hold heavy objects while others snap easily? The secret behind this is something called tensile strength.

Tensile strength is like a superhero power that tells us how strong a material is when we pull or stretch it. It’s the ability of something, like a rope, wire, or even metal, to resist breaking when it’s under a lot of pressure. Think of it as a game of tug-of-war between your hands and the material!

For example, steel has a very high tensile strength, which is why it’s used to build bridges and tall buildings. On the other hand, a piece of chalk has very low tensile strength, so it snaps easily when pulled.

What is Tensile Strength?

Tensile strength is a way to tell how strong a material is when you try to stretch it. Imagine you have a rubber band. If you pull on it with your hands, it stretches, right? But if you pull too hard, it will snap. The tensile strength is like the limit of how much you can stretch it before it breaks.

For example:

- A rubber band has low tensile strength because it breaks easily.

- A metal wire has high tensile strength because it can handle a lot more pulling before it breaks.

So, tensile strength is important when making things like bridges, ropes, or even clothes, to make sure they are strong enough for their job.

You May Also Visit It

Copper Zinc Alloys – Step by Step Guide

Cast Iron Melting Temp | Discover Its Industrial Secrets

Is Aluminium Magnetic Material | Types, Uses and Properties

Physical Properties Are Shared by Most Metals

History

Tensile strength, the ability of a material to resist breaking when being stretched, has a long history in science and engineering. It started being studied in the 19th century when scientists and engineers began to explore the behavior of different materials like metals, rubber, and fabrics under stress. In the early days, engineers were especially interested in how materials would hold up under tension in construction, such as when building bridges or ships.

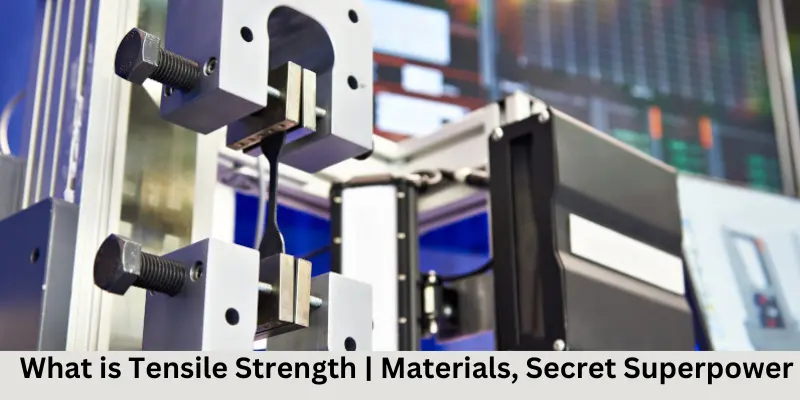

One of the key moments in the history of tensile strength was in the late 1800s when scientists developed ways to measure how much force materials could handle before they broke. This led to the creation of the “tensile test,” where a material sample is pulled until it breaks. In the early 20th century, advances in technology allowed for more precise measurements, and this knowledge helped make materials stronger and safer for use in everyday products.

By the mid-1900s, scientists and engineers had developed better tools, like universal testing machines, to test the tensile strength of a wider range of materials. This led to better design of products such as cars, airplanes, and even toys. Today, tensile strength is one of the most important factors in designing strong materials, from the steel in skyscrapers to the plastic in everyday products

Types

When we talk about tensile strength, we are talking about how strong a material is when we pull it. There are three main types of tensile strength:

1. Yield Strength

- Imagine you are pulling a rubber band. At first, it stretches a little, but after a point, it stretches too much and does not go back to its original shape. Yield strength is the point where the material starts to change shape and can no longer go back to how it was before. It’s like when the rubber band becomes loose and won’t snap back.

2. Ultimate Tensile Strength (UTS)

- This is the maximum amount of pull the material can take before it breaks. If you pull on a rope, there’s a limit to how much you can stretch it before it snaps. The ultimate tensile strength is like the “breaking point” for materials.

3. Breaking Strength

- This is the final point where the material actually breaks. So, after reaching the ultimate tensile strength, the material can’t hold on anymore and will snap or break apart. It’s the moment when the material can no longer hold together.

How is Tensile Strength Measured?

Tensile strength is measured by performing a special test on the material to see how much force it can handle before it breaks. Imagine you have a rubber band. If you pull on it slowly, it stretches. But if you pull too hard, it snaps. The test for measuring tensile strength is similar.

To measure tensile strength, a piece of the material is stretched in a machine that pulls on it. The machine slowly pulls the material until it either gets really stretched or breaks. The machine measures how much force it takes to stretch or break the material.

The formula to calculate tensile strength is:

- σ = F/A – eq 1

- σ = stress

- F = force

- A = area

This just means that we divide how strong the material is by how big the piece of material is. This helps us know how much force it can handle based on its size.

For example:

- If a metal wire can hold 100 pounds before breaking, and the wire is very thin, it might have a high tensile strength.

- If a thicker piece of metal can hold 200 pounds before breaking, it would also have a good tensile strength, but since it’s thicker, it would hold even more weight.

This test is important because it helps us understand how strong materials are, so we can use the right materials for different jobs, like building bridges or making clothes.

Material Tensile Strength Examples

- Rubber Bands

- Tensile Strength: Low

- Example: Rubber bands can stretch a lot, but they break easily if pulled too hard. That’s because their tensile strength is not very high. They are designed to stretch, but not withstand a lot of pulling force.

- Steel

- Tensile Strength: High

- Example: Steel, like the metal in bridges or cars, has very high tensile strength. It can hold a lot of weight without breaking. This is why we use steel to build strong things like skyscrapers and trains.

- Nylon (like in ropes)

- Tensile Strength: Medium to High

- Example: A rope made of nylon, like the one you might use for climbing or tug-of-war, can stretch a little, but it won’t break easily. Its tensile strength is strong enough to support heavy loads without snapping.

- Glass

- Tensile Strength: Low

- Example: Glass, like the windows in your house, has a low tensile strength. It can break easily if you pull or press on it the wrong way, which is why glass shatters when dropped.

- Aluminum

- Tensile Strength: Medium

- Example: Aluminum, like the material used in soda cans, is strong but lightweight. It has enough tensile strength to hold its shape, but it bends more easily than steel.

Why Does Tensile Strength Matter?

The tensile strength of a material helps engineers and designers decide what to use for different jobs. For example, steel is used to make tall buildings because it can hold a lot of weight. But rubber bands are great for holding things together for a short time because they stretch without breaking right away.

What Affects Tensile Strength?

Tensile strength is how strong a material is when it’s stretched. Several things can make a material stronger or weaker when it’s pulled, and here’s how:

- Material Type: Different materials have different strengths. For example, metal is much stronger than rubber. This is because metals are made of atoms that stick together very tightly, making them hard to stretch.

- How the Material Is Made: The way a material is treated or prepared can change its strength. If you heat up metal and then cool it quickly, it might become stronger. This is called heat treatment.

- Size and Shape: A thicker piece of material is harder to stretch than a thinner one. Also, some shapes, like a long, skinny wire, might stretch more easily than a short, thick one.

- Temperature: The temperature can make a material stronger or weaker. Metal can get weaker if it is very hot, while some plastics might get stronger in cold temperatures.

- Time and Repeated Stress: If a material is stretched many times, like rubber bands, it can lose strength over time. This happens because the material gets tired, just like we do after a lot of work.

Applications

Tensile strength is important because it helps us know which materials are strong enough to use in making things like buildings, cars, or even clothes. Think of it like this: if you were building a bridge with a rope, you need to know how much weight the rope can hold before it breaks. That’s what tensile strength tells us!

Here are some examples of where tensile strength is used:

- Building Materials: Materials like steel are used to build strong buildings and bridges because they have high tensile strength. This means they can hold up heavy loads without breaking.

- Wires and Cables: Wires, like the ones in power lines, need to be made from materials with good tensile strength. They need to hold up without snapping, even if a lot of weight is hanging on them.

- Clothing: Some clothes, like jackets or backpacks, are made from strong materials that can stretch a little without breaking. This is important so that the clothes last a long time.

- Cars and Airplanes: Engineers use materials with high tensile strength to make car parts and airplane wings. This helps them stay strong and safe, even when flying through the air or driving fast.

Tensile strength helps us choose the right materials for these things so that they are safe, strong, and can last a long time.

Tensile Strength in Different Materials

Tensile strength is how strong a material is when it gets pulled. Different materials can handle different amounts of pulling before they break. Let’s look at a few examples to see how strong different materials are:

- Steel: This is one of the strongest materials. It is used in buildings, bridges, and cars because it can handle a lot of pulling without breaking.

- Aluminum: Aluminum is lighter than steel but still pretty strong. It’s often used in airplanes and kitchen foil.

- Titanium: This material is very strong and does not break easily, even in very hot or cold conditions. It’s used in things like airplanes and even in some medical tools.

- Plastic: Plastic can have a weaker tensile strength, which means it might break or stretch more easily than metals like steel or titanium. But it’s still used for many things like bottles, bags, and toys.

You May Also Visit It

What is Ferrous vs Non Ferrous Metals – Complete Guide

What is Titanium Steel – Types, Uses, Properties and Modern Metal

Plasma Cutter How Does It Work – Complete Guide

Is Copper a Metalloid | Understanding the Classification of Elements

Why is Tensile Strength Important When Making Products?

Tensile strength helps engineers choose the right materials for building strong and safe products. Imagine building a bridge. The materials used must be strong enough to handle the weight of cars and trucks without breaking. If the materials do not have enough tensile strength, the bridge could collapse.

In many things we use every day, like phones, cars, and airplanes, the materials need to have the right amount of tensile strength. This way, they can withstand pressure or stretching without breaking. If engineers did not think about tensile strength, we might end up with products that break easily or are unsafe to use.

What is Tensile Strength Failure?

Tensile strength is the ability of a material, like a piece of rope, a metal wire, or even a rubber band, to withstand being stretched or pulled apart without breaking. When a material reaches its tensile strength, it can handle a lot of pulling force. However, if the force gets too strong, the material fails or breaks. This is called tensile strength failure.

How Does Tensile Strength Failure Happen?

Imagine you are playing tug-of-war with a rope. If both sides pull too hard, eventually the rope will snap. This happens because the force being applied to the rope has become too much for the rope to handle. The rope’s tensile strength is the maximum amount of force it can take before it breaks.

When the rope or material reaches its breaking point, the fibers or parts inside the material start to stretch too far, and the material can’t hold together anymore. That’s when the failure happens, and the material breaks apart.

Examples of Tensile Strength Failure

- Rope in Tug-of-War: If you pull on a rope too hard, it can break. This is an example of tensile strength failure.

- Rubber Band: If you stretch a rubber band too much, it snaps. This also happens because of tensile strength failure.

- Steel in Buildings: Engineers use steel in buildings because it’s very strong. But even steel has limits, and if it’s stretched too much, it could snap.

Advantages of Tensile Strength

Tensile strength helps materials like steel and rubber stay strong and stretch without breaking, making them perfect for building strong bridges, cars, and even your favorite toys

| Advantages |

|---|

|

Disadvantages of Tensile Strength

While tensile strength helps us understand how strong a material is, it can also be misleading because some materials might break suddenly without warning, and others might only be strong in certain conditions, like when they’re not too hot or cold.

| Disadvantages |

|---|

|

Challenges and Innovations

When scientists and engineers try to make things like bridges, cars, or airplanes, they need to think about how strong the materials are. This strength is called tensile strength how much pull or stretching a material can handle before it breaks. But sometimes, materials like steel or plastic can’t be strong enough, especially in extreme conditions like very hot or cold weather.

Challenges are things that make it hard to use certain materials, like:

- Some materials might break easily if they get too hot or cold.

- Other materials might be too heavy, making them difficult to use in things like airplanes or rockets.

Innovations are new and better ideas or discoveries. Scientists are always looking for ways to improve materials so they are even stronger and safer. Some examples are:

- New materials: Engineers are developing special materials that can handle more stress and last longer, like stronger metals or tough plastics.

- Better tests: Researchers are finding new ways to test materials to make sure they are strong enough for real-world use. This helps avoid accidents and makes products safer.

FAQs About

Why is Tensile Strength Important?

- Tensile strength is important because it helps us know how strong a material is. Engineers use it to choose the best materials for building things like bridges, cars, and even clothes! If a material has high tensile strength, it can be stretched a lot without breaking.

How Do We Measure Tensile Strength?

To measure tensile strength, a special machine pulls on the material until it either stretches or breaks. The amount of force the material can handle before breaking is its tensile strength. The stronger the material, the higher the number.

Can All Materials Have Tensile Strength?

Yes, every material has tensile strength. Some materials, like steel, have high tensile strength and can handle a lot of force before breaking. Other materials, like chalk, have low tensile strength and break easily when pulled.

What Happens When a Material Reaches Its Tensile Strength?

When a material reaches its tensile strength, it either stretches too much and becomes weaker or breaks. For example, if you keep pulling a rubber band, it will either snap or lose its shape.

Does Temperature Affect Tensile Strength?

Yes! When it gets hotter or colder, the tensile strength of a material can change. For example, some materials may become weaker in the heat and break easier, while others can become stronger in cold weather.

What is the Difference Between Yield Strength and Tensile Strength?

Yield strength is the point when a material starts to bend or stretch, but it does not break. Tensile strength is when the material can’t stretch anymore and actually breaks apart. Think of it like stretching an elastic band until it just snaps that’s tensile strength.

Conclusion

Tensile strength is like the “toughness” of a material. It tells us how much a material, like metal, plastic, or rope, can stretch or pull before it breaks. Imagine trying to stretch a rubber band if you pull too hard, it snaps. The rubber band’s tensile strength is how much force it can handle before breaking.

Different materials have different tensile strengths. For example, steel is much stronger than rubber, so it can handle more force without breaking. Engineers use tensile strength to help make things like bridges, cars, and even clothes strong and safe.

In simple words, tensile strength is important because it helps make sure that the things we use every day can handle the pull or stretch without breaking.

You May Also Visit It

Cast Iron Melting Temp | Discover Its Industrial Secrets

Metal Stamping Aluminum | Easy Steps to Understand Metal Stamping

Diagram of V8 Engine Explore the Power Behind Every Part

Welding Position | Types, Properties and Uses – Pros and Cons

What is Cold Roll Steel: Types, Grades and Uses | Pros and Cons

Please Write Your Comments