Types of Flames in Oxy Acetylene Welding – Need Metals

Updated: 03 Dec 2024

907

Imagine when you blow air into a campfire to make it burn brighter. The fire changes because of the extra air. In welding, we do something similar but use two special gases oxygen (like the air we breathe) and acetylene (a gas that burns very hot). When we mix these gases and light them, they create a very powerful flame. Types of Flames

This flame is like a tool it can cut, join, or shape metals. But we need to adjust it carefully, like tuning a radio, to make it work just right for different tasks.

There are three types of flames:

- A neutral flame is balanced and perfect for most jobs.

- A carburizing flame adds extra “fuel” (acetylene) and is good for soft metals.

- An oxidizing flame has more oxygen, making it super hot for harder metals.

The right flame makes all the difference, just like using the right brush when painting a picture.

Types of Flames

In oxy-acetylene welding, we use three types of flames to help us weld different metals. These flames are made by mixing two gases: oxygen and acetylene. Let’s look at each flame and how it works:

- Neutral Flame

- Carburizing Flame

- Oxidizing Flame

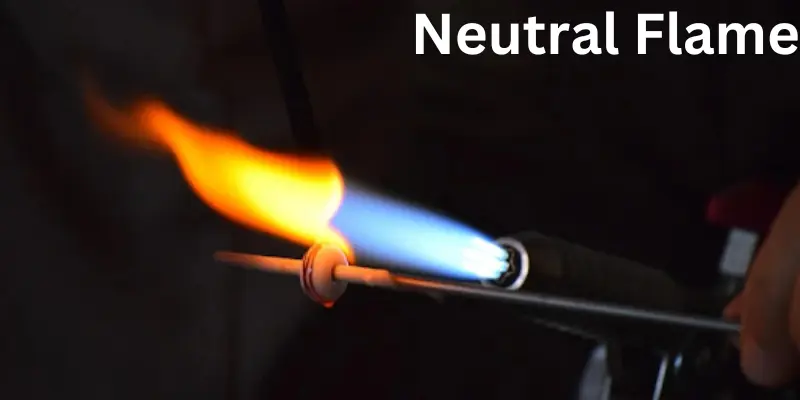

1. Neutral Flame

- What it looks like: A neutral flame has a tiny blue inner cone, and the outer part of the flame is light blue.

- How it works: This flame has a perfect balance between oxygen and acetylene. It’s the best flame to use when you want to weld most metals like steel because it won’t add or take away anything from the metal.

- What it’s used for: You use this flame for regular welding jobs where you want the metal to stay the same without adding or removing anything from it.

You May Also Visit It

Copper Zinc Alloys – Step by Step Guide

Cast Iron Melting Temp | Discover Its Industrial Secrets

Is Aluminium Magnetic Material | Types, Uses and Properties

Physical Properties Are Shared by Most Metals

Advantages of Neutral Flame

The neutral flame in oxy-acetylene welding is balanced, making it ideal for most welding tasks because it doesn’t add or take away anything from the metal being worked on

| Advantages |

|---|

|

Disadvantages of Neutral Flame

A neutral flame in oxy-acetylene welding is not very hot compared to other flames, which means it might not work well for certain jobs like cutting thick metals or metals that need extra heat to melt

| Disadvantages |

|---|

|

1. Carburizing Flame

- What it looks like: The inner cone is still blue, but there’s a white feather of acetylene gas sticking out from it.

- How it works: This flame has more acetylene than oxygen, so it doesn’t burn the metal completely. Instead, it leaves some extra carbon behind.

- What it’s used for: It’s good for working with metals like aluminum or copper that don’t do well with too much oxygen. It can also be used for things like welding lead or carbon steel, where the surface needs to be hardened.

Advantages of Carburizing Flame

The carburizing flame in oxy-acetylene welding is useful because it helps protect metals like steel and aluminum from getting too hot or oxidized, making them easier to work with.

| Advantages |

|---|

|

Disadvantages of Carburizing Flame

A carburizing flame can be harmful because it adds extra carbon to the metal, making it brittle and more likely to crack or break.

| Disadvantages |

|---|

|

3. Oxidizing Flame

- What it looks like: The inner cone is small and turns purple. The flame looks very sharp and intense.

- How it works: This flame has more oxygen than acetylene, which makes it burn hotter. It can be very powerful, but it’s not good for all metals because it can damage them.

- What it’s used for: This flame is used when you need a really hot flame, like when you want to weld metals that need extra heat, such as brass, zinc, or some types of iron.

Advantages of Oxidizing Flame

An oxidizing flame is helpful in oxy-acetylene welding because it burns hotter, making it perfect for tasks like cutting and welding tough metals such as brass and bronze.

| Advantages |

|---|

|

Disadvantages of Oxidizing Flame

An oxidizing flame can be dangerous because it’s too hot and can burn or damage some metals, making them weak and brittle.

| Disadvantages |

|---|

|

How to Adjust Different Flames

In oxy-acetylene welding, you need to control how much oxygen and gas (acetylene) mix together. The mixture creates different types of flames: neutral, carburizing, and oxidizing. Here’s how you can change the flame for each type:

1. Neutral Flame

- First, start with a flame that looks balanced. You get this by making sure the amount of oxygen and acetylene are equal.

- You will see two parts: a small blue flame inside (called the inner cone) and a bigger blue part around it (called the outer envelope).

- The neutral flame is perfect for many welding jobs, especially when you need to work with metals like steel.

2. Carburizing Flame

- To get this flame, you need to increase the amount of acetylene (gas) and reduce the amount of oxygen.

- The flame will look like it has a white feather coming out of the tip.

- This flame is good for metals that don’t like oxygen, like aluminum and lead, because it keeps them safe from rusting or getting damaged.

3. Oxidizing Flame

- For this flame, you need more oxygen and less acetylene.

- The flame will have a sharp blue tip that burns very hot.

- This type of flame is great when you need to cut through or melt metals that don’t get damaged by oxygen, like brass or bronze.

You May Also Visit It

What is Ferrous vs Non Ferrous Metals – Complete Guide

What is Titanium Steel – Types, Uses, Properties and Modern Metal

Plasma Cutter How Does It Work – Complete Guide

Is Copper a Metalloid | Understanding the Classification of Elements

Applications of Each Flame in Simple Terms

When we use an oxy-acetylene torch to weld, the type of flame we use is very important. There are three main types of flames: neutral, carburizing, and oxidizing. Each flame type is used for different tasks. Here’s how you can think of them:

1. Neutral Flame:

- This flame is balanced. It’s like having the right amount of air and fuel. It’s best when you want to weld most metals, like steel. It works well because the flame isn’t too hot or too cold.

2. Carburizing Flame:

- This flame has more fuel (acetylene) than oxygen. It’s like a soft, warm flame that doesn’t burn the metal too much. We use this flame for metals that don’t like too much heat, like aluminum or lead. It can also make metals harder, which is helpful in some jobs.

3. Oxidizing Flame:

- This flame has more oxygen than fuel. It’s super hot and can burn really fast. This is used when we need to work with metals like brass, bronze, or even cast iron. But be careful! It can also make metals brittle, so it’s not always the best for everything.

When to Use Each Flame

- Neutral Flame: Best for general welding, like fixing steel or making metal parts stick together.

- Carburizing Flame: Ideal for soft metals like aluminum or lead, where we don’t want to add too much oxygen.

- Oxidizing Flame: Great for metals like brass, but we should avoid using it on things that burn easily, like iron.

Common Mistakes and Helpful Tips

When you are using the oxy-acetylene flame for welding, it’s important to get the flame just right. If you do not, the weld might not work properly. Here are some mistakes people make and tips to help:

- Mistake: Flame is too big or too small

- What happens: If the flame is too big, it can burn the metal too much. If it’s too small, it won’t heat the metal enough to melt it.

- Tip: Start with a neutral flame (the right balance of oxygen and acetylene) and adjust it until you see a soft, steady flame. It should have a tiny blue inner cone.

- Mistake: Flame is too hot (oxidizing flame)

- What happens: This flame is too strong and can burn the metal or make it weak.

- Tip: If you hear a loud “hiss,” it means the flame is too hot! Make sure you’re using the right flame for the job, like a neutral flame for most welding tasks.

- Mistake: Flame is too cool (carburizing flame)

- What happens: This flame is too cold and doesn’t heat the metal enough. It might also add too much carbon to the metal.

- Tip: Adjust the acetylene and oxygen valves slowly to get the right amount of both gases.

- Mistake: Not adjusting the flame during welding

- What happens: Sometimes, the flame needs to be adjusted while you’re welding to keep the heat steady.

- Tip: Always check your flame while welding. If it changes, fix it to make sure your weld is clean and strong.

What is oxy-acetylene welding?

Oxy-acetylene welding is a method of welding where a special torch is used to mix two gases: oxygen and acetylene. When these gases burn together, they create a very hot flame that can melt metals to join them together.

What are the three main types of flames in oxy-acetylene welding?

There are three main types of flames used in oxy-acetylene welding:

- Neutral Flame: This flame has the perfect balance of oxygen and acetylene. It’s the most common flame used for welding and works well for many metals like steel.

- Carburizing Flame: This flame has more acetylene than oxygen. It’s cooler and is good for welding materials like aluminum, brass, and copper.

- Oxidizing Flame: This flame has more oxygen than acetylene. It’s very hot and is used for metals like brass and cast iron but can cause some metals to get damaged if used incorrectly.

Why is the neutral flame special?

The neutral flame is special because it burns cleanly with no extra oxygen or acetylene. It has a small blue inner cone, and it’s the best flame to use when you want to make strong and clean welds on most metals, like steel.

What is the carburizing flame good for?

The carburizing flame is best for materials that are sensitive to heat and oxidation, like aluminum and brass. It’s also useful when you want to add carbon to the surface of metals, which makes them harder.

What is the oxidizing flame used for?

The oxidizing flame is very hot and has more oxygen than acetylene. It’s used for welding metals like cast iron, brass, and zinc. However, it can make some metals, like steel, brittle and weak, so it’s important to use it carefully.

How do I know which flame to use?

It depends on the material you are welding.

- Use the neutral flame for most regular welding.

- Use the carburizing flame when working with metals that can easily be damaged by too much oxygen, like aluminum.

- Use the oxidizing flame for metals that need a very hot flame, but be careful not to damage the material.

How do I adjust the flame?

To adjust the flame, you turn the knobs on the torch that control the flow of acetylene (the fuel) and oxygen. Start with a neutral flame, and then you can adjust the amounts of each gas to create a carburizing or oxidizing flame.

Why is the color of the flame important?

The color of the flame tells you if the mixture of oxygen and acetylene is just right. A blue flame means the gases are balanced (neutral flame), while a yellowish or white flame means there’s too much acetylene (carburizing flame), and a sharp blue inner cone means there’s too much oxygen (oxidizing flame).

What happens if I use the wrong flame?

If you use the wrong flame:

- A carburizing flame might make the metal too soft or brittle.

- An oxidizing flame could burn or damage the metal, making it weaker. That’s why it’s important to use the right flame for the material you are working with.

Can I weld without adjusting the flame?

You can start welding with a neutral flame, but if you need to weld special materials, you should adjust the flame to get the best results. Adjusting the flame helps make sure the metal doesn’t get damaged or that the weld is strong.

Conclusion

Different types of flames in oxy-acetylene welding is important for anyone learning how to weld. The neutral flame is the most balanced, providing the right heat for most tasks, like welding steel. The carburizing flame has more acetylene, which helps when working with metals like aluminum or copper, as it prevents oxidation.

On the other hand, the oxidizing flame has more oxygen and creates the hottest flame, which is best for cutting metals like brass or bronze. By knowing how to adjust the flame correctly, welders can get the best results, whether they’re joining metals or cutting them. Each flame has its special purpose, and choosing the right one for the job is key to a successful weld.

You May Also Visit It

Cast Iron Melting Temp | Discover Its Industrial Secrets

Metal Stamping Aluminum | Easy Steps to Understand Metal Stamping

Diagram of V8 Engine Explore the Power Behind Every Part

Welding Position | Types, Properties and Uses – Pros and Cons

What is Cold Roll Steel: Types, Grades and Uses | Pros and Cons

Please Write Your Comments