Welding Tables | Complete Guide | Metals

Updated: 14 Dec 2024

231

From home workshops to industrial using high width tables, as a welder, you will need welding tables for big scale jobs and consider the types of welding tables to buy. Table for welding is one of the most essential equipment required by metals workers. Whether you are a professional or a home based DIY welder, obtaining the most suitable welding table works wonders in making quality, safety, and efficiency in the quality of output from welding. These specially designed tables must be stable and flat because they can withstand high heat, pressure, and wear, meeting the requirements of various welding techniques.

These are some aspects of welding tables that will be looked into the different types now available in the welders market, what they can do, and what can make a difference in choosing the right table for your work. Industrial type major tables or tables for smaller scale work their entire range of varieties would have thus been studied for better choice making such as those types perfect for home workshops. Essential accessories, care tips, where to discover the hottest deals, and anything else are also included so that you can get the best during the investment.

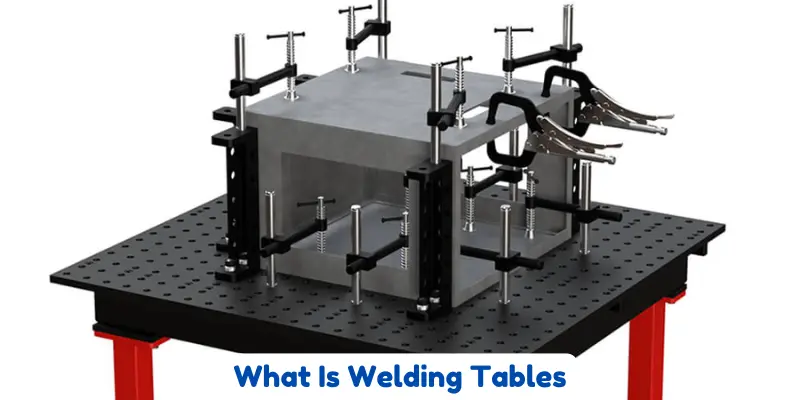

What Is Welding Tables?

Welding tables are simply tables where people do some work when welding metal bits to each other. Welding is a process of using a lot of heat to melt metal and attach it to other pieces. Generally, a welding table has been made compact and strong to withstand high temperature or heat of the process without damage.

Welding tables typically consist of strong materials such as steel and a flat surface to ensure the components being worked on are well held. Some welding tables even have additional features such as holes or clamps that will keep the pieces of metal in that position while you weld. It makes the task much easier and safer.

They come in different sizes. Some are little, which will be fine if only for home use, while others are large and built to take a blow in the industrial world. A good welding table by definition gives you the right helo into doing your work more accurately, safely, and comfortably.

You May Also Visit It

Copper Zinc Alloys – Step by Step Guide

Cast Iron Melting Temp | Discover Its Industrial Secrets

Is Aluminium Magnetic Material | Types, Uses and Properties

Physical Properties Are Shared by Most Metals

Why Welding Tables Are Important

Welding tables are more than just a flat surface to work on they are essential tools that help make welding safer, more efficient, and precise. Here is why having the right welding table is so important:

1. Enhanced Security

- Stable Surface: A welding table provides a solid, steady surface over which barrelling accidents will never happen with no unevenness or shakiness around work areas.

- Resistant To Heat: Welding creates a lot of heat, but a good welding table is made using heat resistant materials, which prevent it from warping or turning into fire hazard.

2. Increased Precision

- Flat Surface: For the accurate welding, the surface is flat enough with the following properties. It lines up your metal together to make a better quality of weld.

- Clamping Features: Most welding tables feature clamps or holes to hold your metal in place for working on fine details without having to move pieces.

3. Improved Productivity

- Well Organized Workspace: A welding table keeps tools and materials organized within arm’s reach and saves time.

- Ergonomic: Height adjusting tables reduce the strain on your body with long projects.

4. Strength and Longevity

- Durable Materials: Welding tables are made primarily of steel, so they last long and resist all forms of use: heavy usage or light occasional use.

- Protects Other Surfaces: A welding table specifically aids in avoiding burns, scratches, or heat damage to your floors or wooden surfaces.

A welding table is probably the best equipment to ensure safety, accuracy, and efficiency during a task as it guarantees that work can be done properly while protecting one is workspace and tools.

Types of Welding Tables

Welding tables come in different types, each designed to meet specific needs depending on the kind of welding work you do.

1. General Welding Tables

These are the most basic rigid flat surfaces used for performing any welding jobs. They usually have a steel making them appropriate for small to medium workpieces. Although they are not too complex, they meet the general requirements for welding.

2. Modular Welding Tables

These are adjustable according to the need of the workpiece. Suitable clamps and extensions can be fixed onto the table at required positions and removed later according to the sizes of projects. Although modifiable, it is also most practical for use by those who have a variety of projects and find flexible arrangements necessary.

3. Heavy Duty Welding Tables

Heavy duty welding battlegrounds is meant for massive industrial welding. These are heavier and large compared to other welding tables. Most often located in factories or professional shops, it bears heavy metal pieces while being used to accomplish extra stability in rigorous work.

4. Portable Welding Tables

These are lightweight and, therefore, portable the perfect answer for a welder who travels very frequently. It could be a job site or even an individual working from their home. On the downside, smaller dimensions make it lesser than other types but offer great use for welding distinctly.

5. Custom Welding Tables

These tables are built requiring needs. You can add features like greater workspace or unique clamps holding parts in place; making an ideal setup in customizing for persons wishing for a personal environment in their particular tasks design.

When different types of welding tables present their benefits, advantages differ according to the nature of one is work assignment. If it were a simple, portable, or heavy duty table that you needed, there would be a special table for your use.

Key Features of a Good Welding Table

When choosing a welding table, it is important to look for certain features that make it safe, efficient, and comfortable to use. Here are the key features that a good welding table should have:

1. Material that is Robust and Sturdy

A good welding table would be stiff, like steel, to endure the hightemperature effects of welding and survive many years work without damage, with some tables opting for thicker steel for increased durability, especially on heavy duty applications.

2. Flat Surface

It is an immediately flat table surface that weld projects require to keep a straight and true path. An uneven surface will result in misalignment and misalignment issues will reflect in the quality and execution in your welds.

3. Heat resistance

Extreme heat is involved in welding; therefore it must be heat resistant. It should be such that high temperatures cannot warp or damage it during the welding process.

4. Height Adjustability

A few welding tables are adjustable in height, so you can work at a most comfortable level in order to avoid stressing your back or neck. Adjustable tables serve varying uses for different working heights.

5. Clamps and Fixtures

While welding tables come with clamps or holes to hold your metal pieces securely in place, this provides a further level of stability while you work.

6. Size and Space

Determine the size of table needed for the project. If bigger projects, then a bigger table. With smaller tasks, even a smaller table will suffice. As a rule, the table surface should afford sufficient space without overcrowding it.

7. Portability (For Some Users)

If indeed, you need to move your table, you would want a portable welding table. Very lightweight, making them easy to carry around these types of tables are great for on the go or outdoor welding jobs.

This is what will provide your welding table in order by keeping you safe, efficient, and comfortable while also proving durable for ergonometric conditions.

Top Welding Table Brands and Models

If you are looking for a good welding table, it is important to pick a reliable brand that offers quality and durability. Here are some of the top brands and models that many welders recommend:

1. Strong Hand Tools Fit Up Welding Table

- Why it is Great: The Fit Up Welding Table from Strong Hand Tools is very reputed for being highly durable and has adjustments available on the legs, a strong steel frame, and a perforated top for firmly clamping metal pieces.

- Perfect for: For the welder desiring a custom table that will work with large or smaller projects.

2. Hobart Workstation Welding Table

- Why it is Great: Made from heavy duty steel and parts built to ease up large welding projects, Hobart is Workstation Welding Table is a trusted name with a long history in welding. Last but not least, this table is fireproof and pressure resistant.

- Perfect for: Professional welders or those looking for a large heavy duty table to work on large projects.

3. Kreg Precision Welding Table

- Why it is great: For the beginner to the expert, Kreg makes it easy to begin with its Precision Welding Table. Adjustable height wise for comfort, flat and firm surface, and several built in accessories to hold materials securely in place are among the many major selling points.

- Perfect for: Flexibility for welders and a table that grows with skills.

4. TRINITY Portable Welding Table

- Why it is Great: A truly portable product when it comes to strength, but lightweight. This is engineered for transport convenience. Hence, it is best suited for welders who are into field work or in tight spaces.

- Perfect for: Hobbyists or DIY welders who need a table that is easy to move.

5. WeldingTable.com Customizable Tables

- Why it is great: WeldingTable.com specializes in customizable tables, which come in many different sizes and shapes for a workspace built around your needs.

- Perfect for: Welders looking for an exact table for their project or workshop configuration needs.

Welding Table Accessories and Upgrades

Welding tables can be made even better with accessories and upgrades. These add extra features that make your work easier, safer, and more accurate. Lets take a look at some useful accessories you might want for your welding table:

1. Clamps and Holders

- Why it is important: Clamps keep metal parts in place when welding so that they do not move while welding and allows better accuracy in your welding and safety. Some tables may even have built in clamps or slots for adding your own.

2. Magnetic Holders

- Why it is useful: Magnetic holders keep metal parts at specific angles while you work: great for special work such as corner or frame welding.

3. Welding Table Extension Kits

- Why it is useful: If you are looking to get extra space for the larger projects, an extension kit peut extend your workspace. Such kits would essentially be successful for the welders who mostly weld bigger pieces of metal.

4. Adjustable Feet

- Why it is useful: Adjustable feet level the table on an uneven floor hence stabilizing it. This is essential both for security and precision while welding.

5. Workbench Lights

- Why it is useful: Good lighting is everything towards detailed welding work. The welding tables provide with built in lights or workbench lights can be added to facilitate clear vision accompanied by the project.

6. Tool Holders and Shelves

- Why it is important: Organization for tools equates to efficiency and speed in to tool holders or shelves mounted on your table, leaving clamps, rods, and the other stuff within reach so time will not be wasted searching for tools.

7. Welding Table Surface Covers

- Why it is important: Surface covers protect your table against sparks, heat, and damage. They also prolong the life of your table particularly for heavy duty projects, some made from heat resistant materials to protect your workspace.

Adding Accessories to Your Welding Table can make it a Safe, Organised Work Space and Work Efficiently for You to Finish Your Projects with Precision.

You May Also Visit It

What is Ferrous vs Non Ferrous Metals – Complete Guide

What is Titanium Steel – Types, Uses, Properties and Modern Metal

Plasma Cutter How Does It Work – Complete Guide

Is Copper a Metalloid | Understanding the Classification of Elements

Advantages and Disadvantages of Welding Tables

Welding tables are handy tools used for fixing and building metal things. They make work easier and safer.

Benefits of Welding Tables

Welding tables are super helpful tools. They keep metal pieces steady and make welding safer and easier.

| Pros |

|---|

|

Drawbacks of Welding Tables

Welding tables are super helpful for welding, but they have some downsides too. Lets explore their drawbacks in simple and fun ways to understand.

| Cons |

|---|

|

By understanding these advantages and disadvantages, you can decide whether investing in a welding table is the right choice for your needs and what type of table suits your projects best.

Common FAQs About Welding Tables

Welding tables are like workbenches for welders. They help hold metal pieces steady while welding. Lets explore some common questions about these handy tables.

What is the purpose of a welding table?

A welding table provides an extensive, solid surface where the metal parts could lie while the welding is executed by the welding technician on the project. It aids them in working most carefully and safely, allowing the stable platform for their jobs.

Do I actually need a welding table?

A welding table is an excellent investment for anyone who frequently welds or requires very precise results. It secures your work while making it more accurate and helping to organize your workspace. Such characteristics are usually beneficial for the hobbyist or pro who tackles big or detailed projects.

What materials are welding tables made out of?

Typical materials include steel and cast iron. These materials resist high temperatures and wear and tear during welding operations.

Can I make my own welding table?

Indeed, many welders craft their tables. It is recommended, however, that you use strong materials such as steel and that the surface is leveled and stable. DIY welding tables may lack features such as clamps or slots commonly found in professional welding tables.

How much does it cost to have welding tables?

A smaller portable table could cost as little as $100, while a heavier duty one with elaborate features might go for anywhere between $500 and $2000 plus. As with almost everything else, the cost of a welding table varies vastly according to its size, material, and features.

What size of welding table would you get?

The size will depend on the kind of projects you do and the space available. For hand projects, a small table is most probably enough. However, a large table with extensions would be the most suitable for bigger or professional projects.

Is there any portable welding table?

There are some welding tables which are portable in nature and are lightweight, designed so that they could be easily carried from one place to another. Most of these work for smaller sized projects or welders who like to move their complete setups once in a while. But, these portable tables may not be sturdy as some heavy duty tables.

How can I take care of my welding table?

Regular cleaning: Take out the debris and metallic shavings after each use.

Prevent rust: Wipe the table with oil or apply a rust preventative spray on it.

Check for any signs of damage: Inspect the table for any dents or warpage that may affect the accuracy.

Can I use a normal table for welding?

None of the ordinary tables are made to take the fire, the spark, and the weight created by a welding job. It is better to have an actual welding table because it will make your life easier and safer while providing better results.

What kind of accessories are a must for a welding table?

Some essential extra parts are:

Clamps to hold materials

Magnetic holders for angled work

Adjustable feet for leveling

Shelves or tool holders for organizing the working place.

If you still have questions, or if you want help with choosing the best welding table, browse through some materials by trusted brands or consult professionals of welding supplies.

Conclusion

If you are interested in welding, whether a hobbyist or just a professional doing welding work, welding tables are one of the most essential tools you need to have. They are those very handy, heat resistant surfaces, ensuring safety, precision, and efficiency on all projects you are working on. There are so many types, features, and accessories among tables that you have the liberty to choose from or customize one seciffic to your needs.

A quality welding table will have you flying high in no time: organizing your space better, keeping you flowing more efficiently into your work, and improving the quality of your work overall. Look and learn your choices, and then select the one that makes your task easier and so enjoyable.

You May Also Visit It

Cast Iron Melting Temp | Discover Its Industrial Secrets

Metal Stamping Aluminum | Easy Steps to Understand Metal Stamping

Diagram of V8 Engine Explore the Power Behind Every Part

Welding Position | Types, Properties and Uses – Pros and Cons

What is Cold Roll Steel: Types, Grades and Uses | Pros and Cons

Please Write Your Comments